Comprehensive Guide to Vanstron’s UV Curing Oven: The Ideal Solution for Fast Adhesive and Conformal Coating Curing

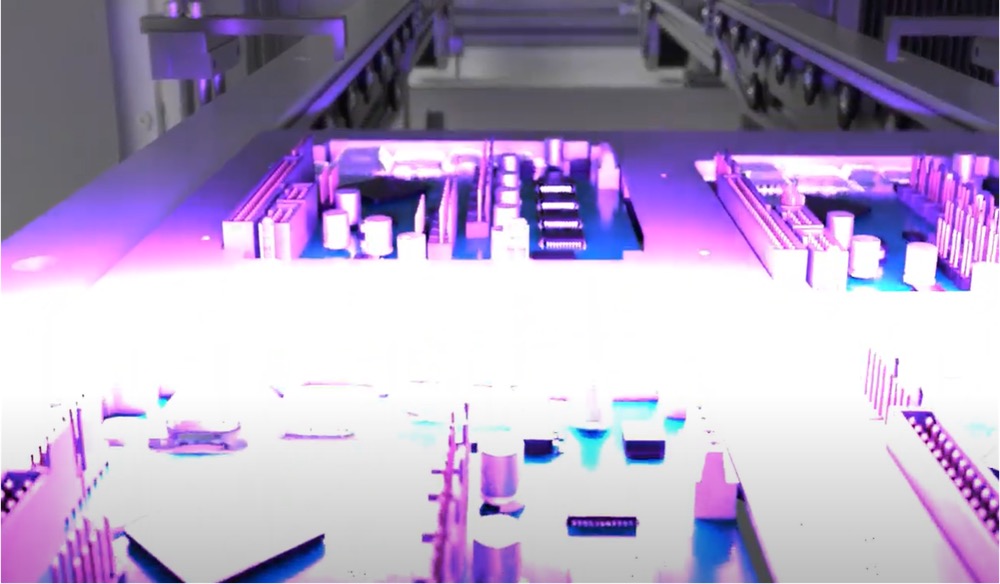

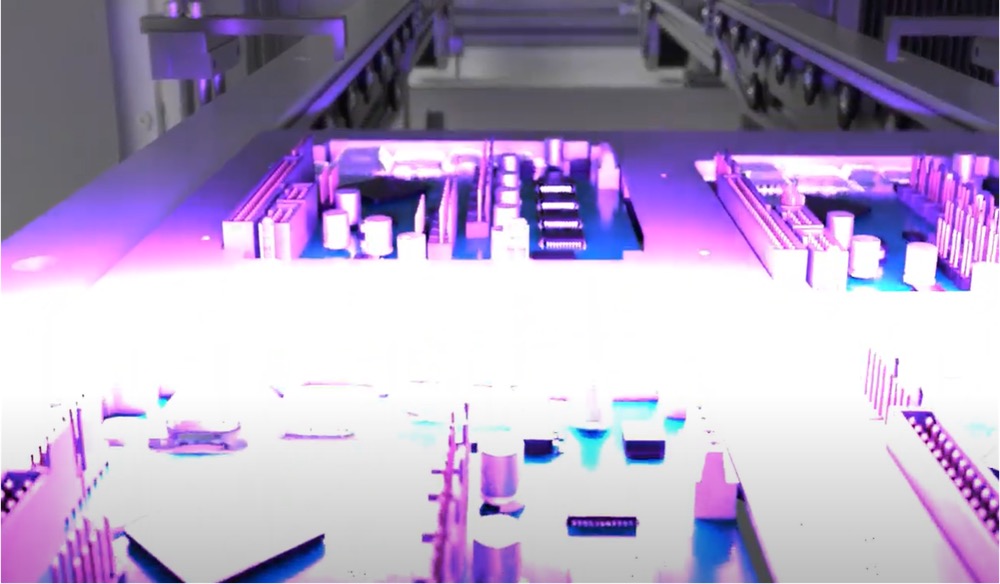

When it comes to UV curing technology, Vanstron’s UV curing ovens stand out as a reliable and efficient choice for industries requiring fast and high-quality adhesive and conformal coating curing. Designed to meet a variety of UV wavelength demands, these ovens leverage Heraeus FUSION UV lamps, a robust mercury-based light source capable of delivering precise curing across UV-A, UV-B, and UV-C spectra. In this article, we’ll delve into the benefits of UV curing ovens, their applications, and key features while highlighting why they are an essential asset for businesses in electronics, manufacturing, and beyond.

What Is a UV Curing Oven?

A UV curing oven is a specialized system that uses ultraviolet light to initiate photochemical reactions in UV-sensitive materials such as adhesives, coatings, and inks. This process solidifies or “cures” the material in seconds, significantly reducing production time while ensuring durability and quality.

Vanstron’s UV curing ovens integrate advanced UV lamp technology and precision engineering to offer exceptional performance in demanding industrial environments.

Features of Vanstron’s UV Curing Oven

1. Heraeus FUSION UV Lamps

Vanstron’s UV curing ovens utilize Heraeus FUSION UV lamps, high-performance mercury-based light sources optimized for versatility and reliability. These lamps deliver uniform energy output across a wide wavelength range:

• UV-A (320–400 nm): Ideal for deep curing and penetrating thicker materials.

• UV-B (280–320 nm): Suitable for surface curing and enhancing material strength.

• UV-C (200–280 nm): Effective for sterilization and high-speed curing processes.

2. Fast Curing Times

Learn how Vanstron’s UV ovens enable rapid curing of adhesives and conformal coatings in seconds, boosting production efficiency and throughput.

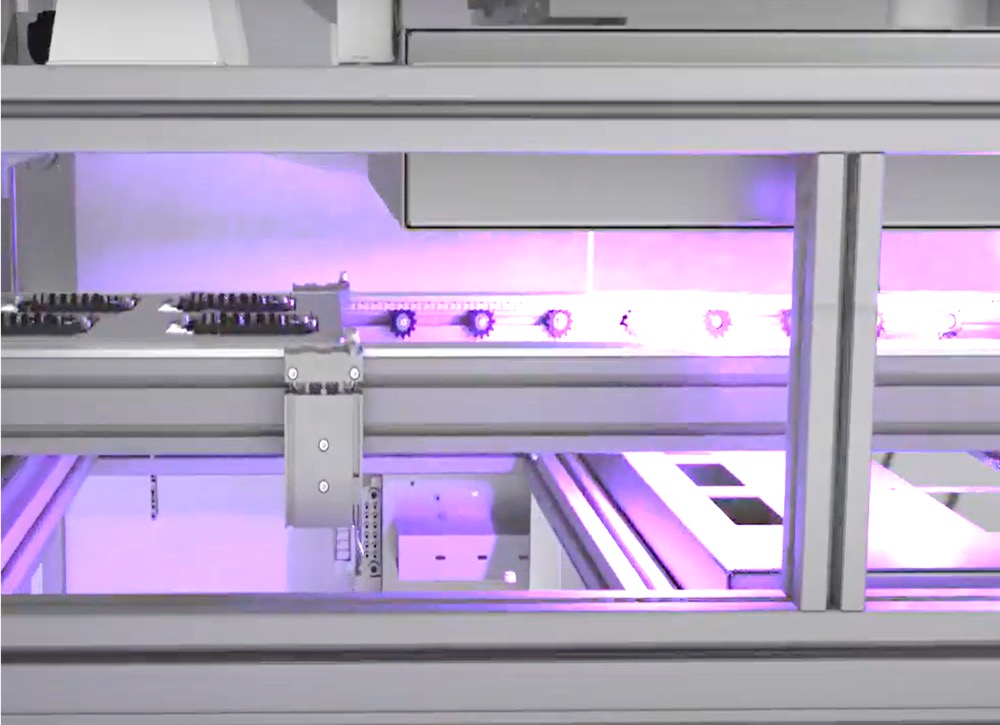

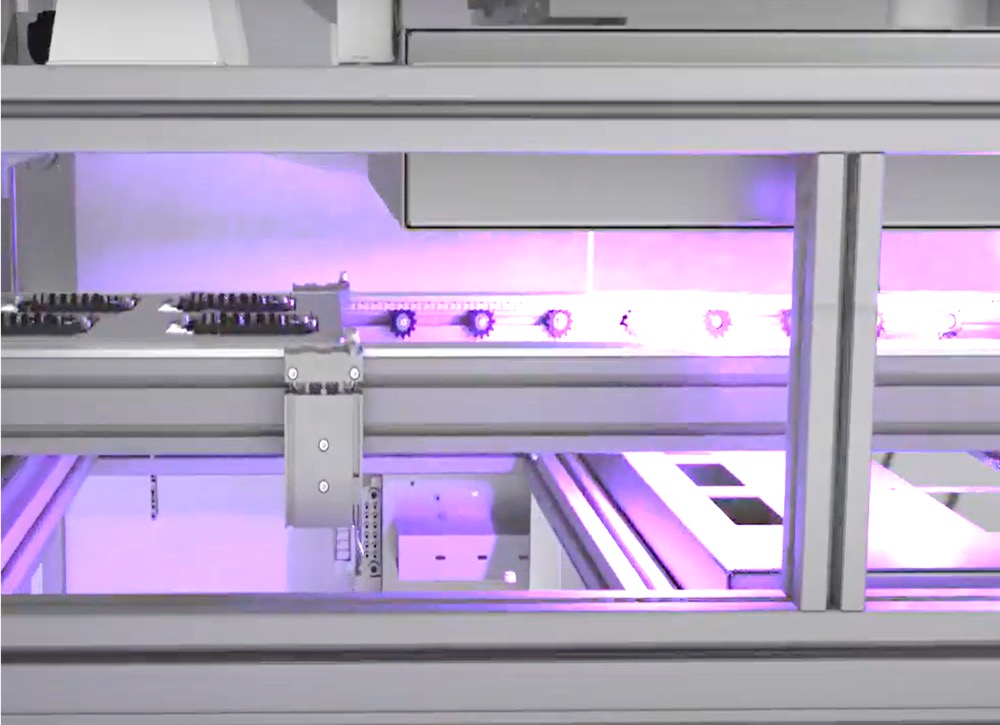

3. Durable Design for Continuous Operation

Built to withstand prolonged operation, Vanstron’s UV curing ovens are ideal for high-volume manufacturing, ensuring consistent performance and reduced downtime.

4. Adjustable Settings for Versatility

Explore the customizable settings of Vanstron’s ovens, including UV intensity, exposure time, and temperature adjustments, to meet diverse application requirements.

Applications of Vanstron’s UV Curing Oven

1. Adhesive Bonding

Discover how Vanstron UV ovens enhance adhesive bonding in industries like electronics, medical devices, and automotive manufacturing.

2. Conformal Coating

Improve the reliability of electronic components with Vanstron’s conformal coating solutions.

3. Optical Devices

Applications like lens assembly and fiber optic bonding benefit from the precision and speed of UV curing.

4. Printing and Packaging

Learn why UV curing is ideal for printing and packaging with its superior adhesion and quick drying times.

Advantages of Using Mercury-Based UV Lamps

While many UV curing systems are transitioning to LED technologies, mercury-based UV lamps like the Heraeus FUSION UV lamps offer unique advantages:

• Broad Wavelength Spectrum: Understand the benefits of broad-spectrum UV curing, suitable for diverse applications.

• Higher Energy Output: Mercury lamps deliver intense energy, enabling faster curing times for high-volume production.

• Cost-Effectiveness: Explore how mercury lamps offer value in industrial UV curing.

Why Choose Vanstron for UV Curing?

1. Industry Expertise

Vanstron’s expertise in UV curing technology ensures every system delivers unmatched performance and reliability.

2. Customizable Solutions

Explore how Vanstron tailors UV curing ovens to meet the unique requirements of different production lines.

3. Sustainability and Efficiency

Learn how Vanstron optimizes energy usage and minimizes waste while delivering high-performance UV curing.

Tips for Optimizing Your UV Curing Process

To maximize the benefits of UV curing, follow these best practices:

• Choose the Right Wavelength: Match your material with the ideal UV wavelength for optimal results.

• Maintain Regular Lamp Inspection: Ensure consistent energy output with proper lamp maintenance.

• Control Environmental Factors: A stable curing environment is crucial for quality results.

• Use Protective Measures: Equip your workspace for safe UV curing operations.

Conclusion

Vanstron’s UV curing ovens, equipped with Heraeus FUSION UV lamps, represent the perfect fusion of performance, versatility, and efficiency for industries demanding high-quality adhesive and conformal coating curing. Whether you’re in electronics, automotive, or manufacturing, Vanstron’s UV systems deliver fast curing times, superior material performance, and long-lasting reliability.

Contact Vanstron today to explore how their solutions can revolutionize your production processes!