Enhancing PCB Traceability with Inline Laser Marking Machines

In the realm of modern electronics manufacturing, PCB traceability has become a critical aspect of quality control and regulatory compliance. Ensuring that every Printed Circuit Board (PCB) is uniquely identifiable throughout its lifecycle is essential for maintaining product quality and meeting stringent industry standards. Inline laser marking machines are at the forefront of enabling precise and reliable PCB traceability, delivering unmatched performance in the electronics manufacturing landscape.

The Importance of PCB Traceability

PCB traceability involves assigning a unique identifier to each board, enabling manufacturers to track its journey from raw material to finished product. This process is vital for:

• Quality Assurance: Learn how traceability identifies and resolves defects efficiently.

• Regulatory Compliance: Explore how traceability supports global standards in industries like automotive, aerospace, and medical devices.

• Process Optimization: Discover how traceability data refines manufacturing processes and reduces waste.

With increasing demand for miniaturized and high-performance PCBs, achieving traceability requires advanced marking technologies that are both accurate and robust.

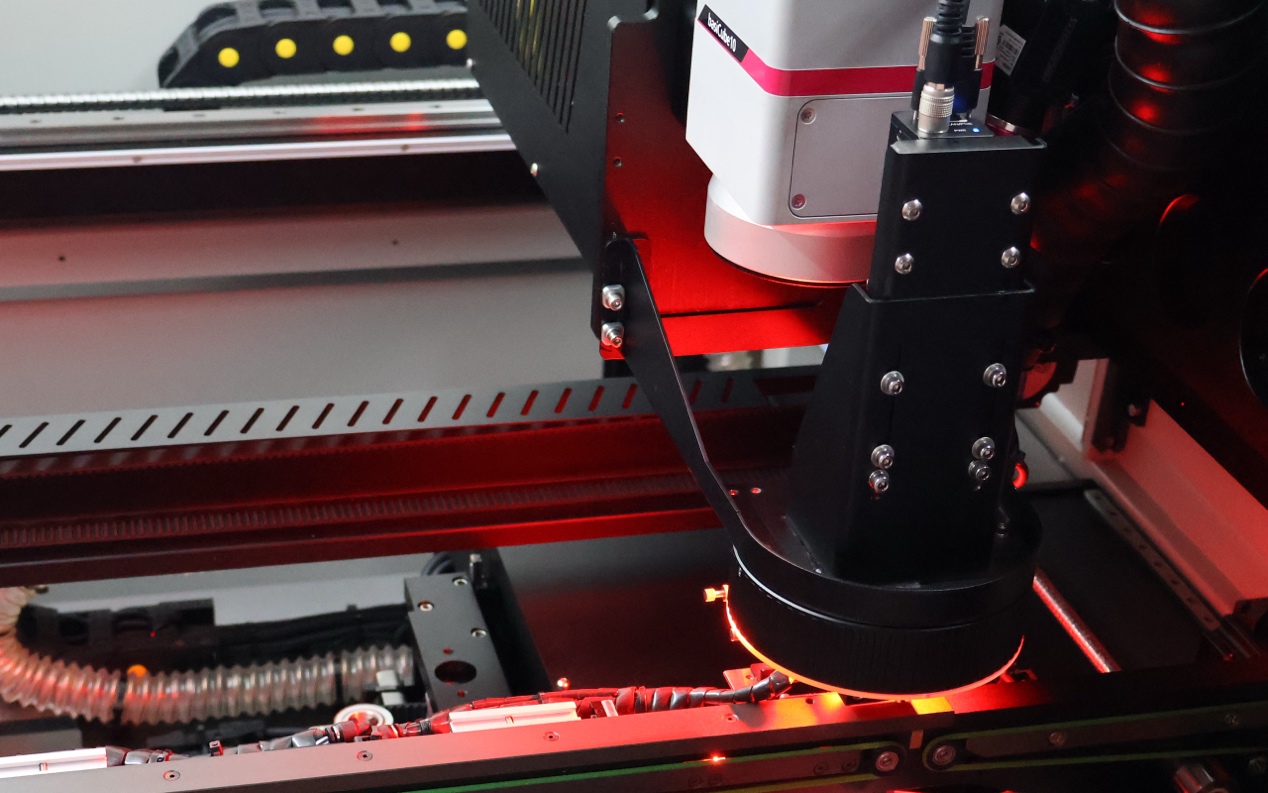

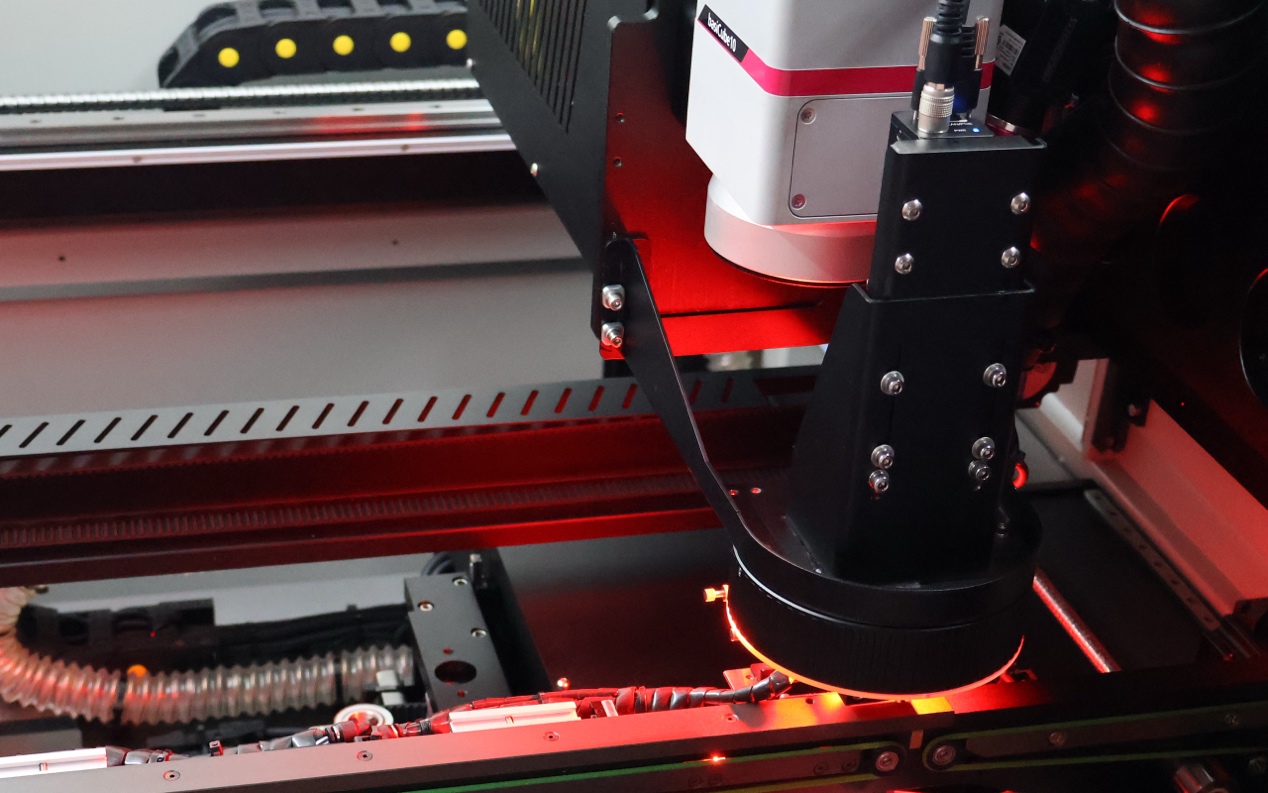

How Inline Laser Marking Machines Revolutionize PCB Traceability

1. Permanent and Precise Markings

Inline laser marking machines deliver high-resolution markings, including QR codes, serial numbers, and barcodes. These durable marks withstand heat, chemicals, and abrasion, ensuring lifetime PCB traceability even in harsh conditions.

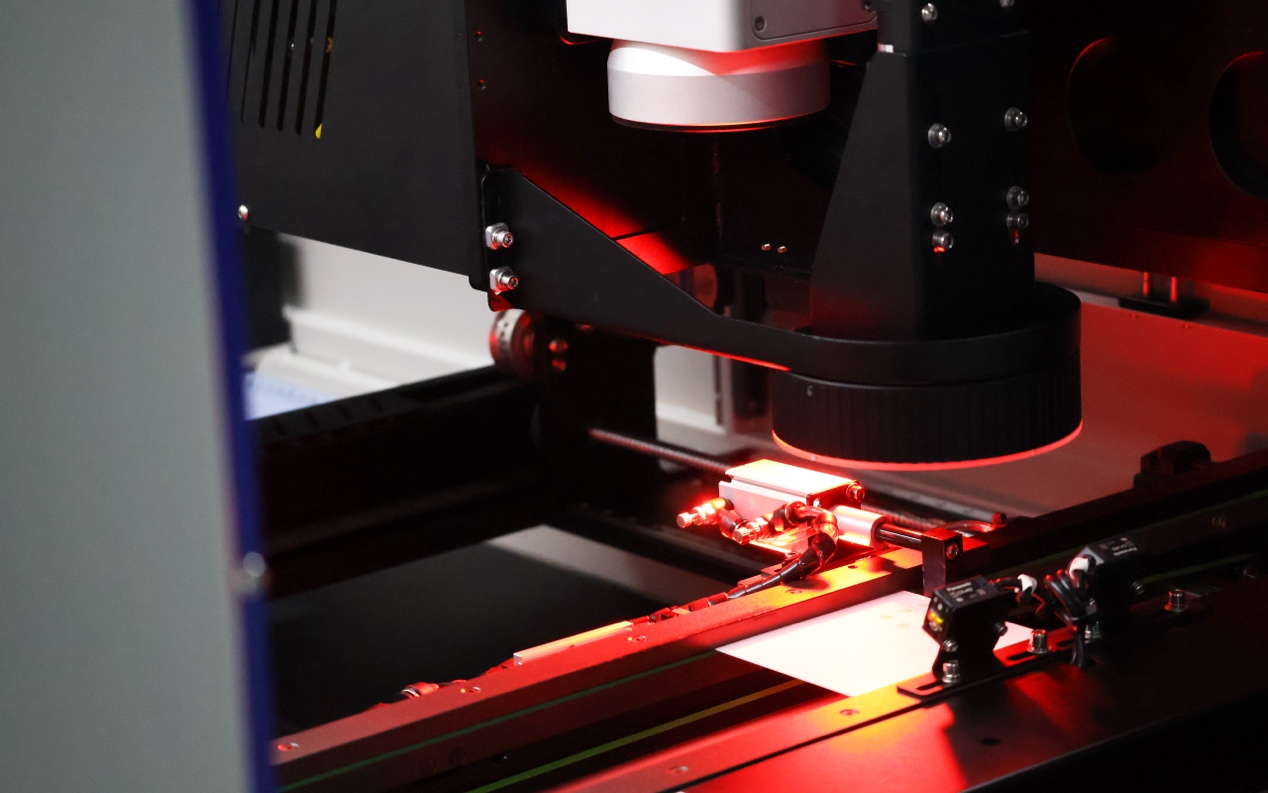

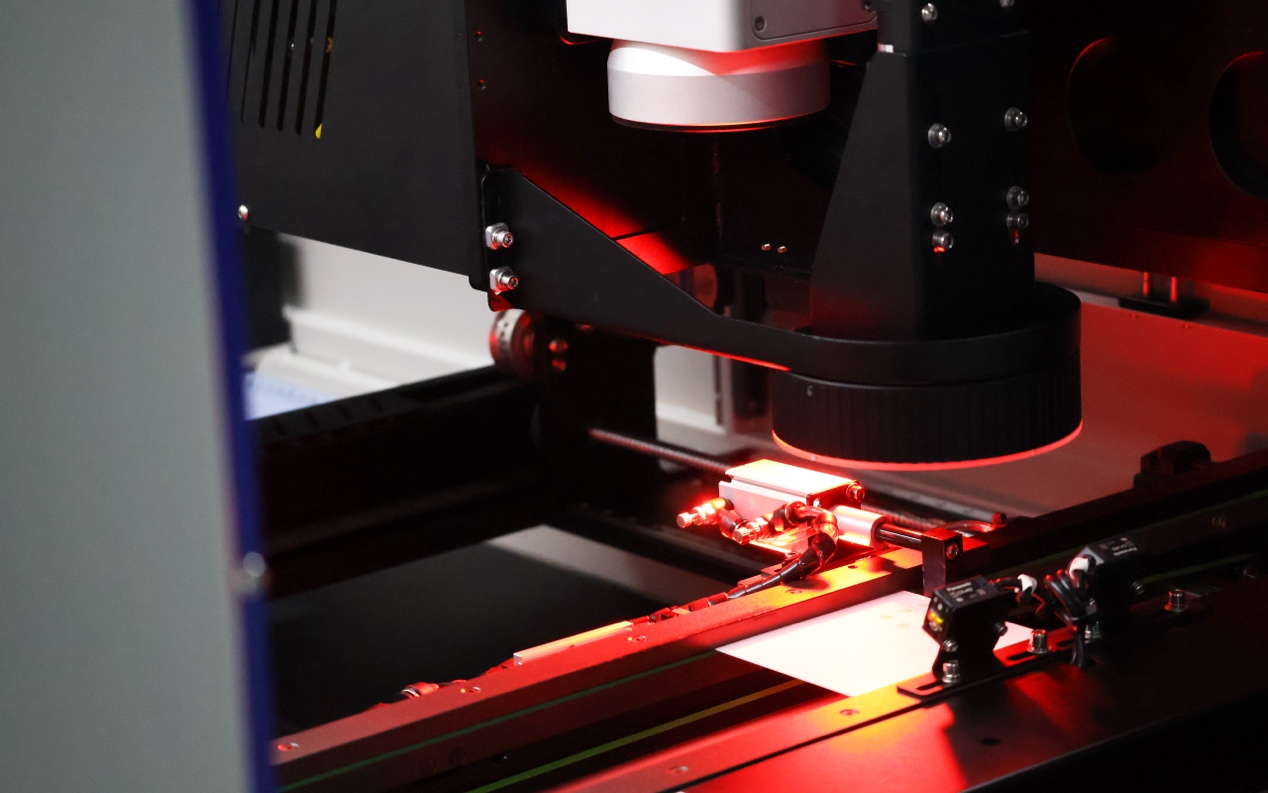

2. Real-Time Marking in SMT Lines

Seamlessly integrate laser marking into SMT production lines for on-the-fly marking without disrupting workflows. High-speed capabilities keep pace with demanding production schedules.

3. Compact and Non-Contact Technology

Non-contact laser marking technology is ideal for delicate PCBs, ensuring legibility even on densely populated boards.

4. MES Compatibility

Integrate with Manufacturing Execution Systems for automated data capture and real-time production monitoring, enhancing traceability and process control.

5. Environmentally Friendly

Laser marking aligns with sustainable manufacturing by eliminating consumable waste, unlike traditional methods such as inkjet printing.

Applications of Inline Laser Marking Machines in PCB Traceability

1. Automotive Industry

Discover how traceability enhances automotive PCB reliability, creating durable identifiers for components like engine control units and sensors.

2. Medical Devices

Explore contamination-free laser marking solutions that meet regulatory standards for medical-grade PCBs.

3. Aerospace Electronics

Laser-marked PCBs provide robust traceability systems capable of withstanding extreme conditions in aerospace applications.

4. Consumer Electronics

Ensure cost-effective traceability in high-volume consumer electronics production without compromising speed or quality.

Key Benefits of Using Inline Laser Marking Machines for Traceability

• Durability: Marks remain intact throughout a product’s lifecycle.

• Scalability: Support high-volume production with precision.

• Efficiency: Integrate seamlessly with automated production lines.

• Data Accuracy: Ensure reliable data capture and management.

• Cost-Effectiveness: Eliminate consumables and minimize maintenance needs.

Vanstron’s Inline Laser Marking Machines: A Superior Solution

At Vanstron, we specialize in advanced inline laser marking systems tailored to meet the unique demands of PCB traceability. Our machines offer:

• High-speed operation: Optimize productivity with Vanstron’s machines.

• Integration-ready designs: Effortlessly integrate into SMT production lines.

• Precision laser technology: Ensure accuracy for compact and intricate PCBs.

• Compliance with global standards: Adhere to IPC and ISO certifications.

• User-friendly software: Enable MES connectivity and seamless operation.

Conclusion

As traceability becomes a cornerstone of modern PCB manufacturing, inline laser marking machines are indispensable tools for ensuring product quality, regulatory compliance, and operational efficiency. Vanstron’s state-of-the-art solutions empower manufacturers to meet these challenges with confidence, providing durable, precise, and scalable marking capabilities.

Contact Vanstron today to explore how our machines can transform your traceability processes and set your business apart.