An Overview of IPC Hermes 9852: The Backbone of Industry 4.0 in SMT Assembly

The IPC Hermes 9852 standard, also known as “The Hermes Standard,” represents a significant advancement in surface mount technology (SMT) assembly lines. It replaces the legacy SMEMA (Surface Mount Equipment Manufacturers Association) standard, addressing the limitations of traditional PCB handling systems in an Industry 4.0 context.

What is IPC Hermes 9852?

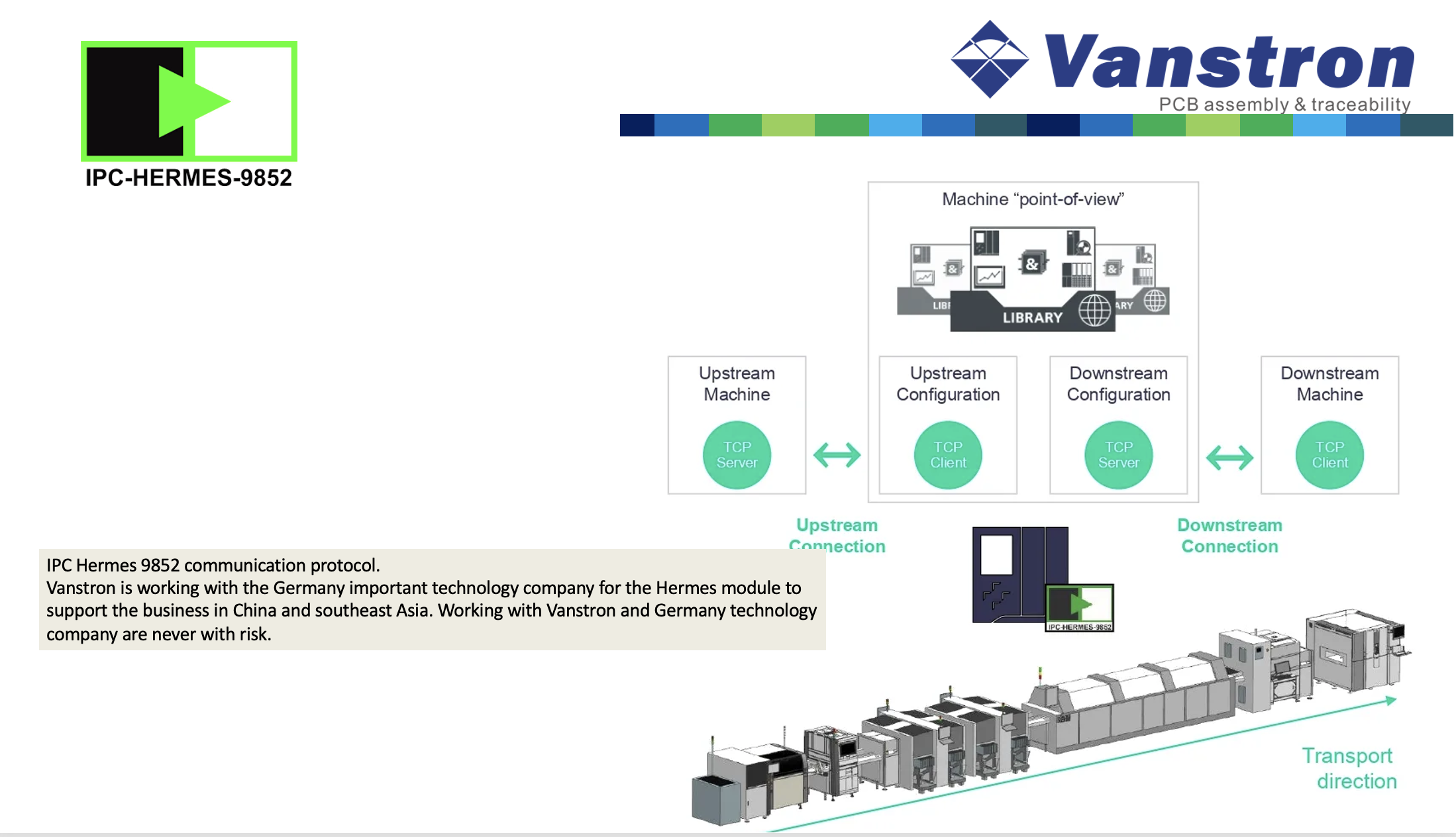

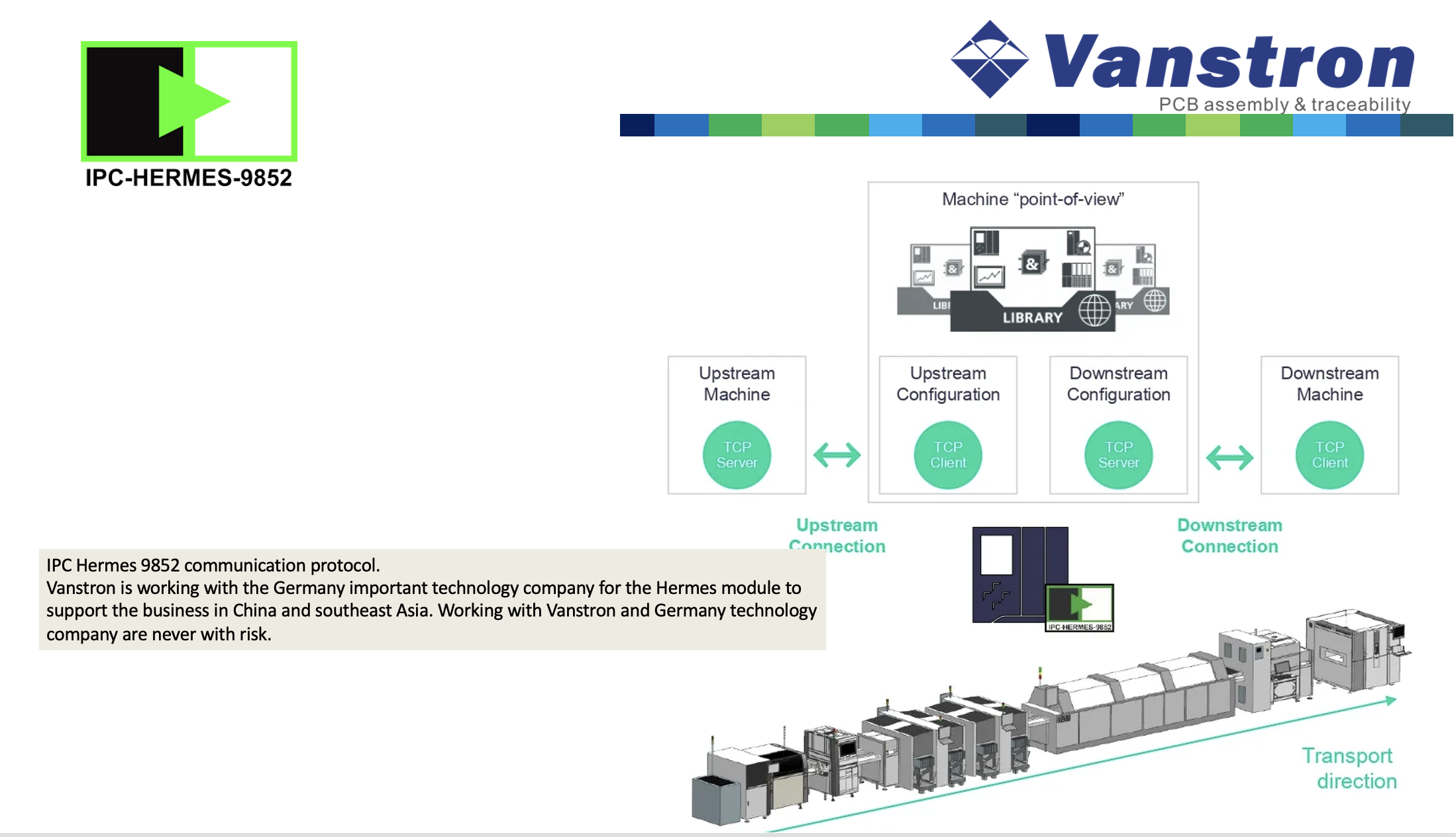

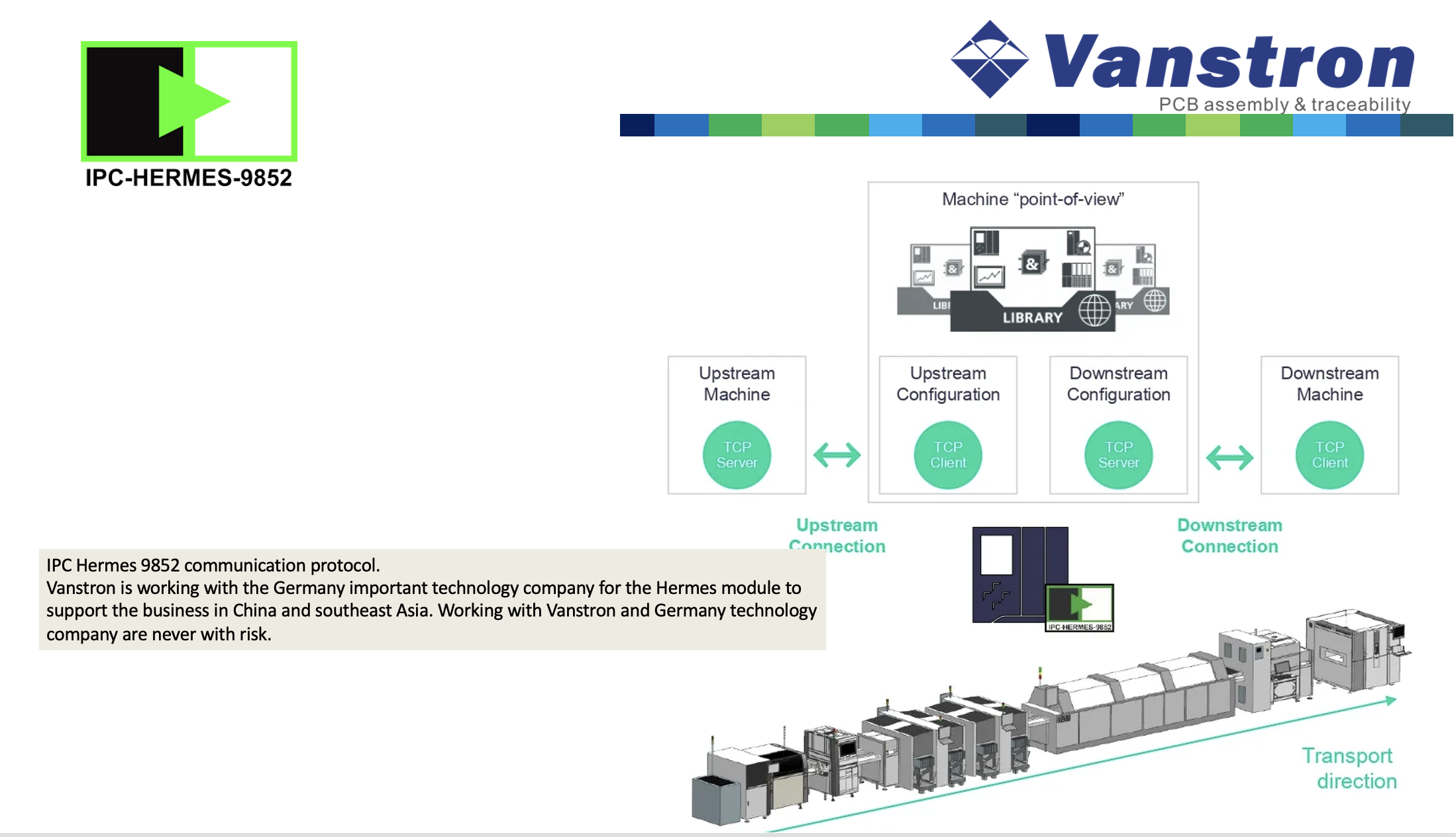

Introduced by the IPC organization, IPC Hermes 9852 is a communication protocol designed to standardize the exchange of information between machines in SMT production lines. The Hermes Standard provides a single, open interface to enable seamless communication without proprietary constraints.

Key features include:

• Machine-to-Machine (M2M) Communication: Facilitates the exchange of PCB information like dimensions, unique IDs, and routing data.

• IP-Based Communication: Operates over Ethernet, allowing high-speed, reliable data exchange.

• Real-Time Data Exchange: Ensures that upstream and downstream machines are synchronized for efficient production.

Advantages of IPC Hermes 9852

1. Eliminates Proprietary Dependencies

The Hermes Standard supports interoperability across different brands and machine types, reducing integration costs and complexity.

2. Enhanced Traceability

It enables detailed tracking of each PCB’s journey through the assembly line, providing critical data for quality control and process optimization.

3. Scalability for Industry 4.0

The protocol is compatible with advanced smart factory systems, allowing for flexible and modular production line setups.

4. Reduced Downtime

Real-time communication minimizes errors and downtime, ensuring smoother transitions between machines and faster response to process disruptions.

Technical Highlights

• Data Structure: Utilizes XML-based messaging for efficient data representation.

• Flexibility: Capable of handling different board sizes, orientations, and data requirements.

• Backward Compatibility: Supports integration with older systems while paving the way for Industry 4.0 capabilities.

Use Cases of IPC Hermes 9852

1. High-Mix, Low-Volume Production

Hermes enhances flexibility in environments where frequent changeovers are required, such as electronics manufacturing for prototypes or custom solutions.

2. Mass Production

In high-volume manufacturing, Hermes ensures consistent data flow and rapid adjustments, critical for maximizing throughput.

3. Advanced Traceability Systems

Companies that need detailed process logs for compliance, particularly in aerospace, automotive, or medical device sectors, benefit greatly from the traceability offered by Hermes.

The Role of IPC Hermes 9852 in Industry 4.0

As manufacturing evolves, smart factories rely on interconnected machines and data-driven decision-making. IPC Hermes 9852 serves as a foundation for these advancements by:

• Integrating seamlessly with IoT devices and MES (Manufacturing Execution Systems).

• Supporting predictive maintenance through real-time monitoring.

• Enabling the adoption of autonomous production systems.

Future of IPC Hermes 9852

The Hermes Standard is continually evolving to support more complex manufacturing requirements. Its alignment with other protocols, like CFX (Connected Factory Exchange), further solidifies its role as a cornerstone of modern manufacturing systems.

Conclusion

IPC Hermes 9852 is more than just a communication standard; it’s a gateway to unlocking the full potential of Industry 4.0. By standardizing M2M communication and enhancing operational efficiency, it empowers manufacturers to achieve higher productivity, improved traceability, and seamless integration into smart factories.

For businesses aiming to future-proof their operations, adopting IPC Hermes 9852 is not just a choice—it’s a necessity in the era of digital manufacturing transformation.

For more information, please visit: https://www.the-hermes-standard.info/