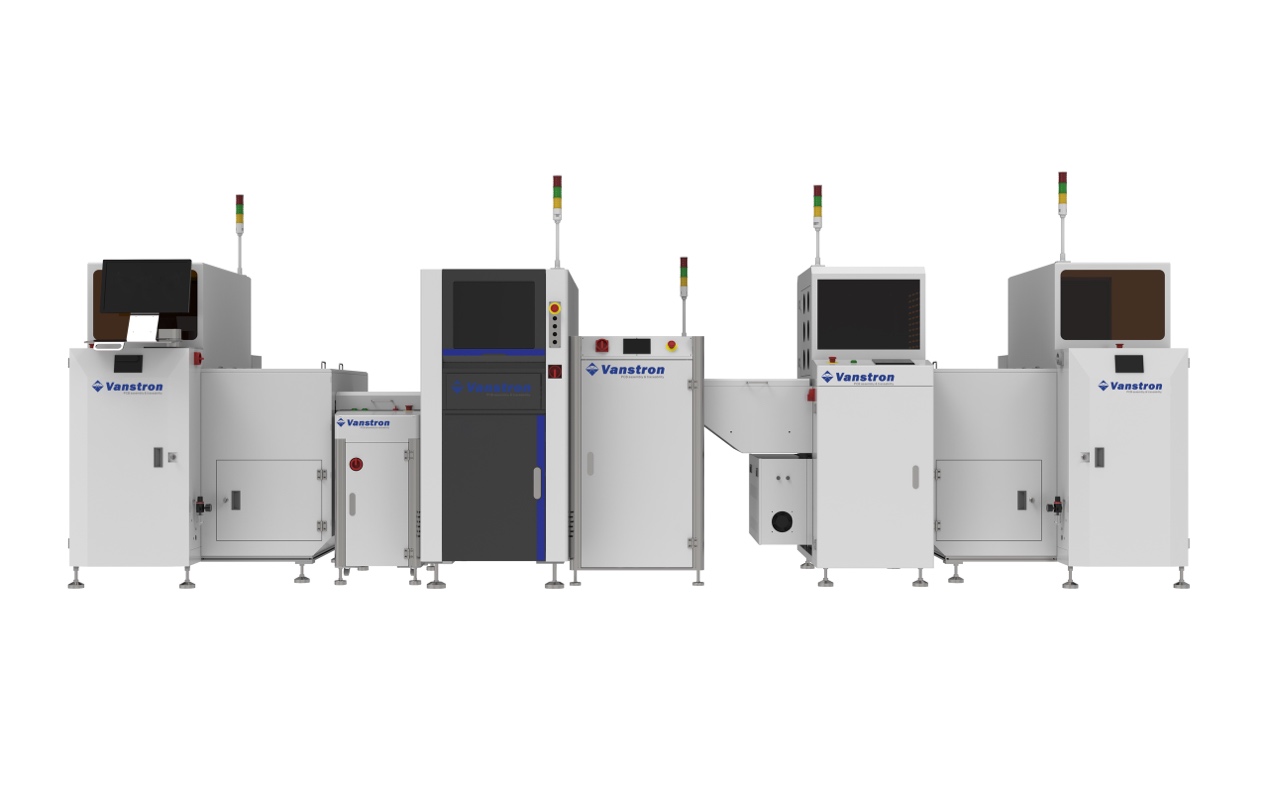

SMT Boards Handling Machines: Vanstron’s Advanced Solutions for Efficient PCB Manufacturing

Introduction

In the fast-paced world of electronics manufacturing, efficiency, precision, and reliability are non-negotiable. Surface-Mount Technology (SMT) is at the core of modern PCB (Printed Circuit Board) production, requiring seamless handling systems to optimize assembly lines. Vanstron’s SMT boards handling machines are designed to meet these needs, providing robust, flexible, and intelligent solutions for handling PCBs across SMT production processes.

This article explores Vanstron’s SMT boards handling machines, their features, applications, and how they can revolutionize PCB manufacturing for industries ranging from consumer electronics to telecommunications and automotive sectors.

What Are SMT Boards Handling Machines?

SMT boards handling machines are specialized automation equipment designed to transport, buffer, align, and manage PCBs within SMT production lines. These machines are integral to improving productivity and reducing manual intervention in tasks such as:

• Loading and Unloading: Moving PCBs to and from conveyors or storage units.

• Buffering: Temporarily holding PCBs for quality checks or synchronization between processes.

• Sorting and Inspection: Organizing and positioning boards for precise assembly.

Vanstron’s handling machines ensure a smooth workflow by eliminating bottlenecks, minimizing damage, and maintaining consistent throughput.

Key Features of Vanstron’s SMT Boards Handling Machines

1. Modular and Flexible Design

Vanstron’s machines are modular, allowing easy customization and integration into existing SMT lines. Adjustable rail widths and height settings accommodate various PCB sizes and thicknesses, making them suitable for diverse applications.

2. Advanced Control Systems

Equipped with PLC (Programmable Logic Controller) technology, Vanstron’s handling machines offer precise control over board movement. Features like speed adjustment, real-time monitoring, and fault detection ensure reliability.

3. High-Speed and Precision Handling

The machines are designed for rapid and accurate PCB transfer, ensuring alignment and minimizing errors during assembly. This is crucial for high-density SMT lines where precision is paramount.

4. ESD Protection

Electrostatic discharge (ESD) can damage sensitive electronic components. Vanstron’s handling machines incorporate ESD-safe materials and grounding mechanisms to protect PCBs throughout the handling process.

5. Compact and Space-Saving

Vanstron prioritizes compact designs that maximize production floor space without compromising functionality, making them ideal for high-volume manufacturing environments.

6. Built for Industry 4.0

Vanstron’s SMT handling machines feature smart connectivity options, enabling integration with MES (Manufacturing Execution Systems) and IoT platforms. This supports real-time data tracking and enhances overall line efficiency.

Applications of Vanstron’s SMT Boards Handling Machines

1. PCB Assembly Lines

From loading raw PCBs into the assembly line to unloading completed boards, Vanstron’s handling machines streamline every stage, reducing labor costs and cycle times.

2. Quality Control Stations

Buffer and inspection conveyors allow PCBs to be temporarily held for testing, inspection, or rework without interrupting production flow.

3. Sorting and Storage

Sorting modules organize PCBs for batch processing, while storage units protect boards from damage or contamination during idle stages.

4. High-Mix, Low-Volume Production

For manufacturers dealing with frequent product changes, Vanstron’s flexible machines adapt to different board sizes and production requirements seamlessly.

Key Models and Their Features

Model Key Features Applications

Vanstron SMT-L Compact loader with adjustable magazine width Loading and unloading PCBs in SMT lines

Vanstron SMT-B Advanced buffering system with intelligent synchronization Quality control and production line balancing

Vanstron SMT-Sorter High-speed sorting and alignment for multiple PCB sizes Sorting for batch or multi-product production

Vanstron SMT-ESD Fully ESD-safe handling for sensitive components High-reliability applications like aerospace

Advantages of Vanstron’s SMT Boards Handling Machines

1. Improved Workflow Efficiency

Automated handling ensures a smooth transition between SMT processes, reducing idle time and increasing throughput.

2. Enhanced Product Quality

Precision handling minimizes misalignment, board damage, or contamination, ensuring higher quality in the final product.

3. Reduced Labor Costs

With automation, manual intervention is significantly reduced, freeing up human resources for other critical tasks.

4. Scalability

Vanstron’s modular designs allow manufacturers to expand their production capacity with minimal disruption.

5. Reliability and Longevity

Built with durable materials and high-quality components, Vanstron’s machines provide consistent performance and long service life.

Industries Benefiting from Vanstron’s SMT Handling Machines

1. Consumer Electronics

Smartphones, wearables, and IoT devices require high-speed, high-precision assembly. Vanstron’s machines ensure smooth handling to meet tight deadlines and quality standards.

2. Telecommunications

In the era of 5G, PCBs for base stations and network equipment require meticulous handling to avoid defects. Vanstron’s ESD-safe machines are ideal for such applications.

3. Automotive Electronics

With the rise of electric vehicles, PCBs for control systems and sensors demand robust handling solutions to meet safety and reliability requirements.

4. Medical Devices

Medical-grade PCBs require clean, damage-free handling. Vanstron’s precision machines meet the stringent demands of this sector.

How Vanstron Machines Align with Industry 4.0?

Vanstron’s SMT handling machines are built with connectivity and smart automation in mind. Features like data logging, remote monitoring, and predictive maintenance support advanced manufacturing strategies, enabling:

• Real-Time Analytics: Monitor production line performance and identify inefficiencies.

• Predictive Maintenance: Reduce downtime with alerts for component wear or failure.

• Seamless Integration: Connect machines with MES and ERP systems for holistic management.

Why Choose Vanstron for SMT Boards Handling Machines?

1. Expertise and Innovation

Vanstron has a proven track record of delivering innovative solutions tailored to the needs of the electronics manufacturing industry.

2. Customization

Vanstron offers customizable options to ensure compatibility with specific production requirements and layouts.

3. Global Support

With a strong support network, Vanstron ensures seamless installation, training, and after-sales service worldwide.

4. Focus on Quality

Every machine is rigorously tested to meet international quality standards, guaranteeing reliability in even the most demanding environments.

Conclusion

Vanstron’s SMT boards handling machines are redefining efficiency and precision in PCB manufacturing. From advanced automation features to ESD protection and Industry 4.0 readiness, these machines offer unmatched value to manufacturers seeking to optimize their production lines. Whether you’re in consumer electronics, automotive, telecommunications, or medical device production, Vanstron’s solutions can transform your operations, delivering consistent quality and throughput.

FAQs

1. What types of PCBs can Vanstron’s handling machines support?

Vanstron’s machines are designed to handle various PCB sizes, thicknesses, and types, including rigid and flexible boards.

2. Are the machines compatible with existing SMT lines?

Yes, Vanstron’s handling machines feature modular designs and adjustable settings for seamless integration into existing production lines.

3. How do Vanstron machines ensure ESD safety?

Vanstron uses ESD-safe materials and grounding mechanisms to protect sensitive components from electrostatic discharge.

4. Can Vanstron’s machines handle high-mix, low-volume production?

Absolutely. The machines are designed for flexibility, making them ideal for frequent product changes in high-mix environments.

5. Are the machines easy to maintain?

Yes, Vanstron’s handling machines are built with user-friendly designs and offer predictive maintenance features for minimal downtime.

6. How do these machines support Industry 4.0 initiatives?

With features like IoT connectivity, real-time monitoring, and MES integration, Vanstron’s machines align perfectly with smart manufacturing strategies.