Why Vanstron Is Different From Other Chinese Competitors

Vanstron Automation has established itself as a premium manufacturer in the SMT industry, distinguishing itself from other Chinese competitors through strategic product innovation, advanced technology, high safety standards, excellent customer service, timely delivery, and a firm commitment to long-term value creation. This paper explores the key aspects that make Vanstron unique and a reliable partner for global SMT enterprises.

1. Strategic Product Portfolio

Vanstron’s product strategy is meticulously designed to address market needs while creating synergies between product lines.

• Advanced Compatibility and Integration:

Vanstron’s core product line, SMT boards handling machines, is engineered to seamlessly integrate into SMT production lines from any global brand. Leveraging advanced communication protocols such as RS-485/232, Ethernet, and IPC Hermes 9852, Vanstron ensures efficient and error-free data exchange. In contrast, most Chinese competitors only offer basic SMEMA compatibility, limiting their flexibility and appeal in diverse manufacturing setups.

• Synergistic Product Development:

Vanstron’s new product development always considers the potential for cross-product sales. For instance:

• The high-quality inline laser marking machine not only addresses customer needs for precise marking but also drives the sales of complementary products like loaders, PCB dust cleaners, and unloaders, forming a complete Laser Island Solution.

• The development of the inline plasma cleaning machine enhances Vanstron’s cleaning solutions, creating a robust product group with PCB dust cleaners and plastic cleaning machines.

This strategic approach not only solves pain points for customers but also maximizes sales opportunities for partners. For SMT professionals and distributors, working with Vanstron means benefiting from innovative product combinations that drive customer satisfaction and long-term growth—something low-innovation Chinese competitors cannot achieve.

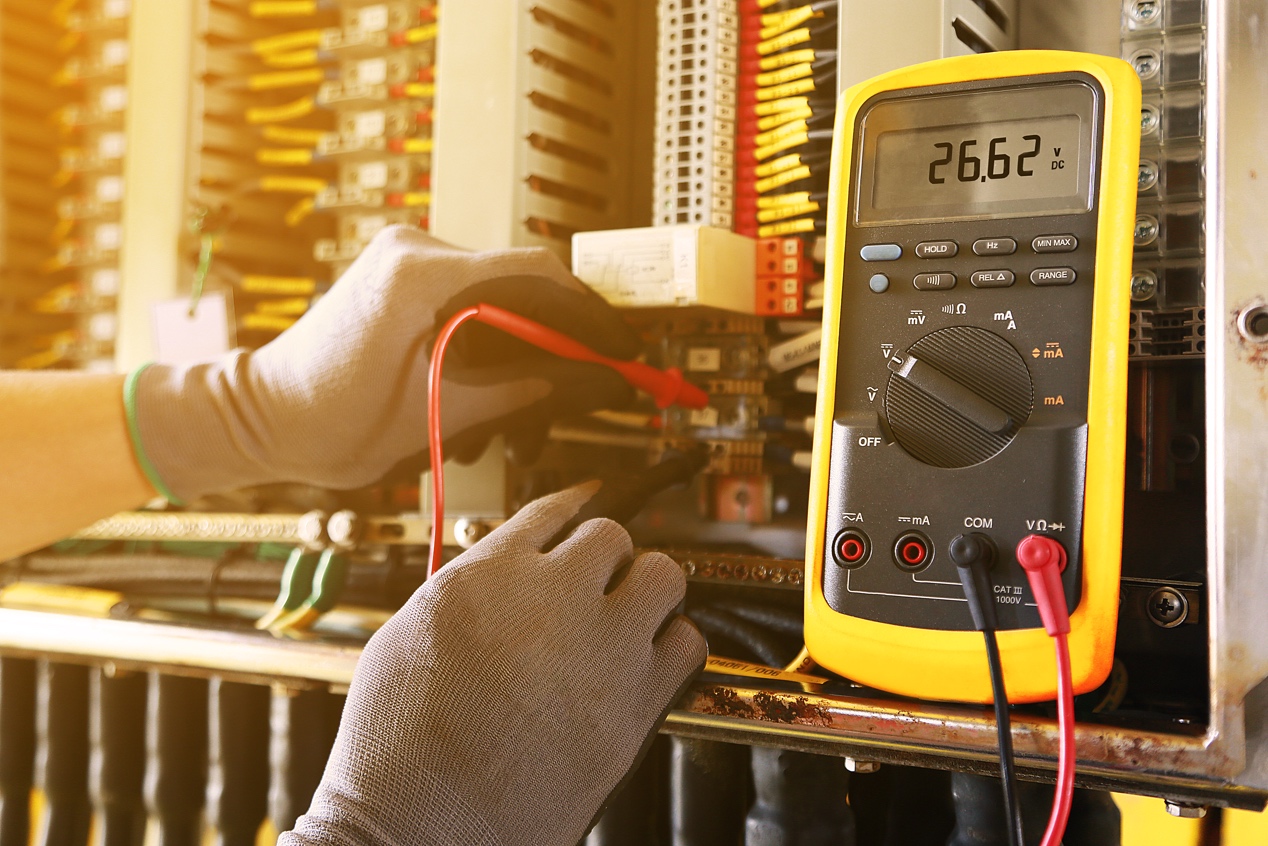

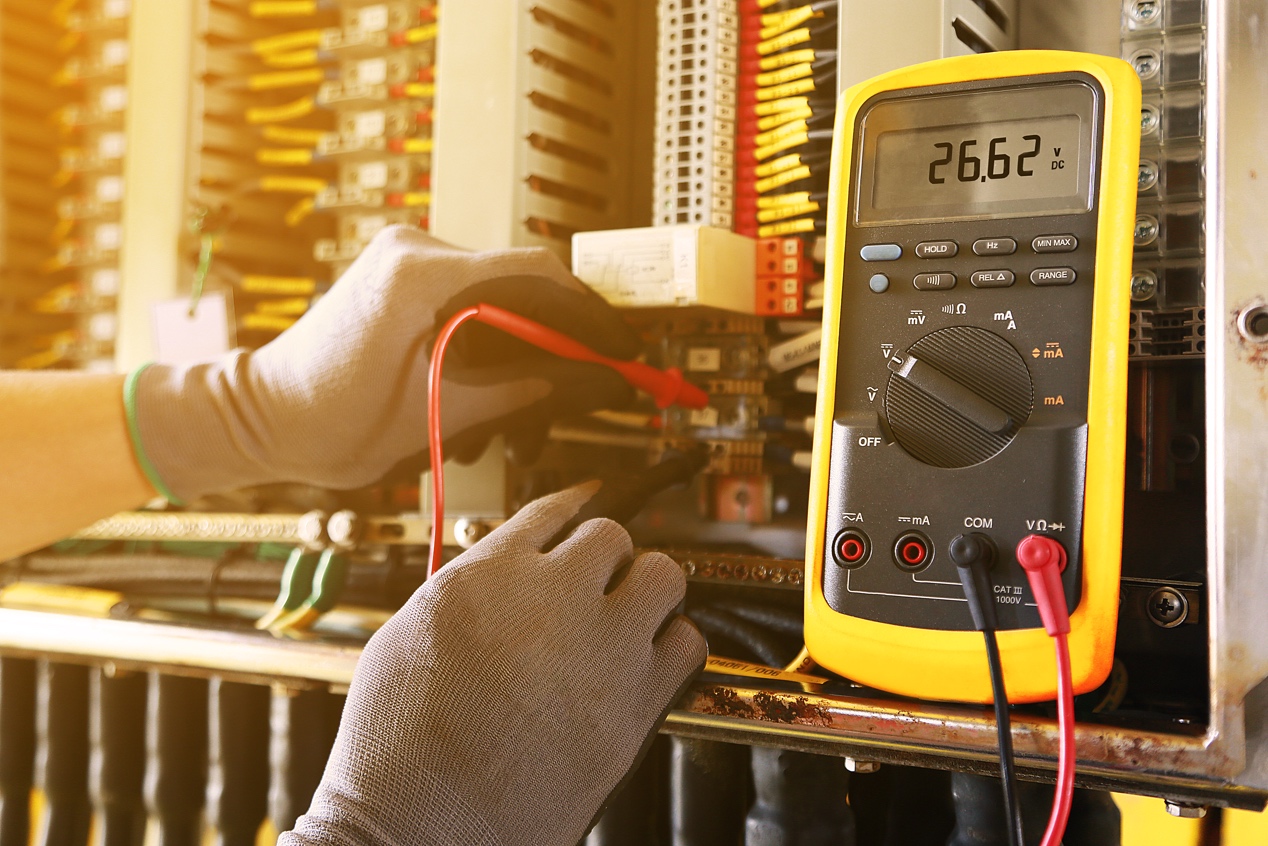

2. Technical Excellence and Safety Standards

Vanstron sets itself apart from other low-end Chinese suppliers by adhering to rigorous international standards in product design and manufacturing.

• Designed for Global Markets:

All Vanstron products are developed based on high-quality European CE standards, from mechanical engineering to electrical safety design. By contrast, many Chinese competitors focus solely on meeting domestic standards, prioritizing cost reduction over safety and performance. Their “cost-down” approach often strips products of essential safety features, resulting in equipment that merely functions but lacks reliability and protection for operators.

• Safety First Philosophy:

Vanstron emphasizes operator safety and product integrity from day one of design. This ensures that every machine not only operates effectively but also provides a secure environment for users and prevents defects in customer products. Customers can trust that any product processed by Vanstron equipment is flawless, safe, and reliable.

3. Customer-Centric Pre-Sales and Post-Sales Service

Vanstron’s service excellence stems from its deep industry expertise and commitment to customer success.

• Pre-Sales Expertise:

With over a decade of SMT industry experience, Vanstron’s core team offers clients valuable insights into industry trends and best practices. This enables Vanstron to:

• Develop innovative solutions based on a thorough understanding of global technological advancements.

• Sell only products that are backed by proprietary core technologies, ensuring that all customer promises are met.

Unlike low-end competitors who often act as intermediaries reselling unoriginal products, Vanstron operates with an engineer’s mindset, valuing technical innovation over quick profits.

• Post-Sales Commitment:

Vanstron is deeply committed to minimizing downtime and maximizing customer satisfaction.

• A robust spare parts management system ensures the availability of components even for machines over 7 years old.

• Comprehensive support guarantees timely resolution of any issue, safeguarding clients against significant production losses.

This level of dedication contrasts sharply with competitors who lack both technical expertise and the infrastructure to provide consistent after-sales support.

4. Reliable and Timely Delivery

Vanstron’s manufacturing capabilities are designed to meet tight deadlines without compromising quality.

• Professional Workforce:

A 45-member production team, all certified professionals, ensures the highest standards of craftsmanship. Vanstron invests in its employees by offering industry-leading salaries and benefits, fostering motivation and dedication to excellence.

• Streamlined Operations:

Adhering to ISO quality management standards, Vanstron oversees every step of the production process—from material procurement and sheet metal fabrication to electrical assembly and machine testing. This ensures:

• Consistent product quality.

• Fast delivery within 25-30 days for most orders.

Vanstron’s commitment to timely delivery helps customers realize a faster return on investment, a critical advantage that many competitors fail to provide.

5. Commitment to Long-Term Value Creation

Vanstron distinguishes itself by embracing long-term principles that prioritize durability, customer trust, and sustainable growth.

• Durability and Reliability:

Vanstron’s machines are built with high-grade components to withstand the demands of continuous industrial use. This minimizes maintenance costs and reduces the total cost of ownership for customers.

• Continuous Improvement:

Feedback from customers is actively incorporated into product development, ensuring that Vanstron solutions remain aligned with evolving industry needs.

• Sustainable Partnerships:

Rather than focusing on short-term profits, Vanstron invests in building enduring relationships with its customers and partners. This approach ensures mutual growth and positions Vanstron as a trusted, reliable partner in the SMT industry.

Conclusion

Vanstron Automation has redefined what it means to be a Chinese SMT equipment manufacturer. By prioritizing advanced technology, safety, superior service, timely delivery, and long-term value creation, Vanstron has emerged as a trusted partner for global SMT businesses. Unlike other Chinese competitors focused on low-cost, short-term gains, Vanstron provides innovative solutions that drive success for its customers and partners, now and in the future.