A Comprehensive Guide for enhancing Electronic Manufacturing with Inline UV Laser Marking Machines.

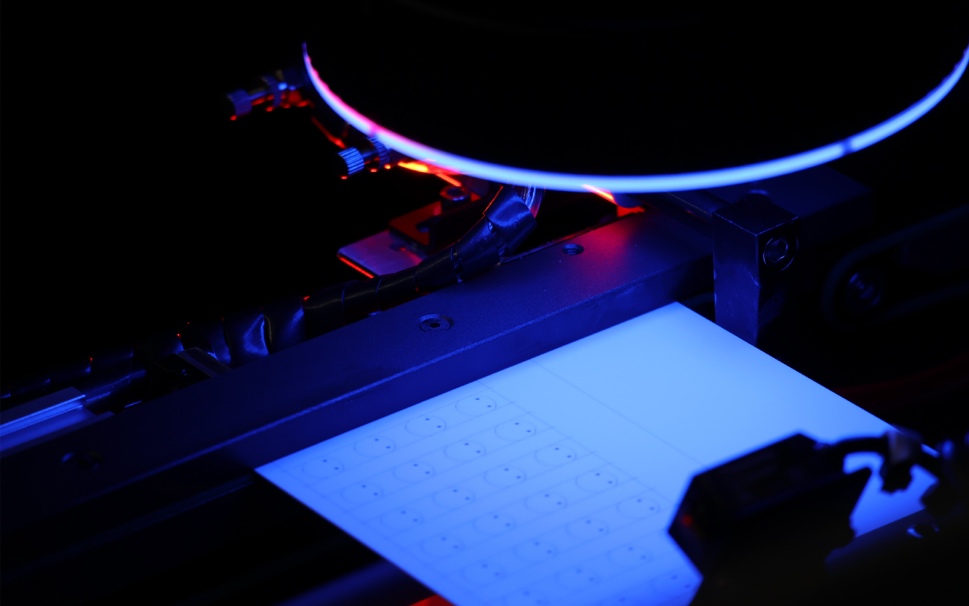

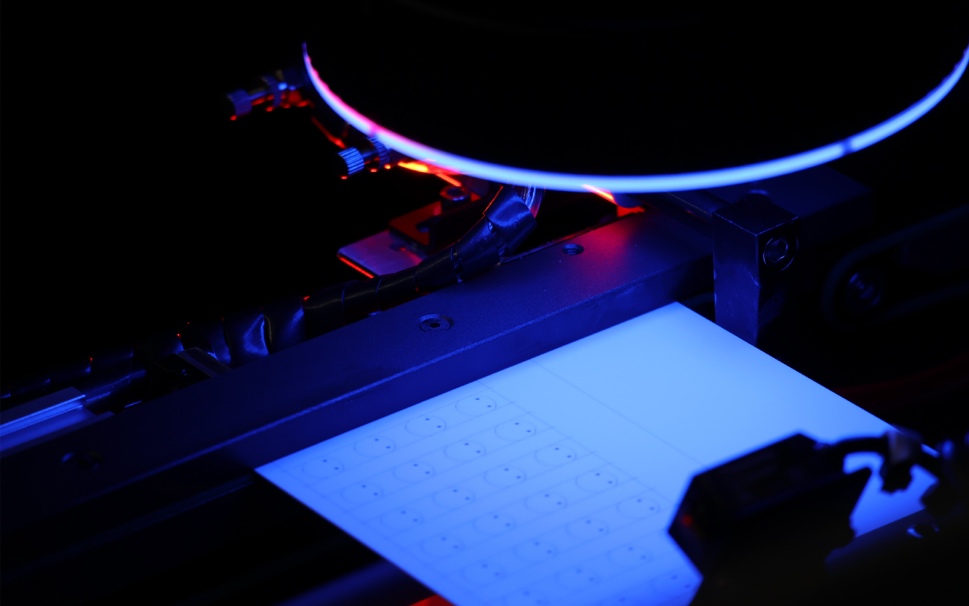

In the highly competitive world of electronics manufacturing, precision and efficiency are key to maintaining a competitive edge. Inline UV laser marking machines have emerged as a game-changing technology, providing unparalleled accuracy and versatility. Among the top solutions in this category is Vanstron inline UV laser marking machine, known for its advanced features and exceptional performance.

I Why UV Laser Marking is Essential in Electronics Manufacturing

Why UV Laser Marking is Essential in Electronics Manufacturing

UV laser marking uses a high-frequency laser to etch fine and intricate marks on various materials, making it ideal for printed circuit boards (PCBs) and other electronic components. This technology enables manufacturers to achieve:

1. Permanent, High-Quality Marking – Ensuring durability and resistance to wear.

2. Precise Marking on Compact Components – Critical for modern electronics with reduced dimensions.

3. Traceability – Improved product tracking through 2D barcodes or serial numbers.

Key Applications of Inline UV Laser Marking Machines from Vanstron

Inline UV laser marking machines are indispensable in several electronics manufacturing processes:

• PCB Marking: Creating alphanumeric characters, logos, or 2D barcodes for identification.

• Bad Mark Recognition: Automatically identifying and marking defective boards to prevent assembly errors.

• Group and Array Marking: Enhancing throughput by marking multiple items simultaneously.

Why Choose Vanstron Inline UV Laser Marking Machine?

Vanstron inline UV laser marking machine stands out with a robust set of features tailored for electronics manufacturing. Here’s what makes it a top choice:

1. Fiducial Recognition: Ensures accurate alignment during marking, even with complex layouts.

2. Single/Double-Side Marking (Optional): Offers flexibility for diverse marking needs.

3. 2D Barcode Quality Check: Verifies barcode readability to maintain traceability standards.

4. Exceptional Accuracy: Marking positioning achieves a CPK >1.67 with precision up to +/-0.015 mm

5. Bad Mark Recognition: Enhances process reliability by automatically detecting defective components.

6. Group Marking and Array Mode: Boosts efficiency with simultaneous marking of multiple units.

7. Anti-Second Marking: Prevents duplicate markings to ensure process integrity.

8. Versatile Color Compatibility: Capable of marking on PCBs in green, white, red, black, purple, and blue.

9. Optional Fume Extraction: Maintains a clean working environment.

10. MES/ERP Connectivity (Optional): Seamless integration with manufacturing systems for real-time data exchange.

11. Long UV Laser Head Lifespan: Provides up to 15,000 hours of operation.

12. RGB Lighting: Optimizes visibility during the marking process.

Advantages of Inline UV Laser Marking in Electronics Manufacturing

The benefits of using Vanstron’s machine extend beyond features:

• Improved Yield Rates: With precise marking and defect recognition.

• Faster Production Cycles: Achieved through group marking capabilities.

• Enhanced Quality Control: Barcode verification ensures compliance with industry standards.

• Sustainability: Fume extraction and low-maintenance UV laser technology reduce environmental impact.

Future-Proof Your Manufacturing with Vanstron

As electronic devices become smaller and more complex, the demand for advanced marking solutions will continue to grow. Vanstron’s inline UV laser marking machine provides manufacturers with the tools they need to stay ahead in the industry, ensuring high-quality, reliable, and efficient production processes.

Invest in Vanstron technology today and experience the difference precision marking can make in your production line. For more details, contact us or visit our website! www.vanstron.com