The Integration of IPC Hermes 9852 Standard in Vanstron’s Boards Handling Machines

In the rapidly advancing field of SMT (Surface Mount Technology) automation, seamless communication and data exchange between equipment are crucial for optimizing production processes. Vanstron, a leader in SMT automation solutions, has integrated the IPC Hermes 9852 communication standard into its range of boards handling machines, reinforcing its commitment to delivering state-of-the-art, intelligent, and interconnected manufacturing solutions.

What is the IPC Hermes 9852 Standard?

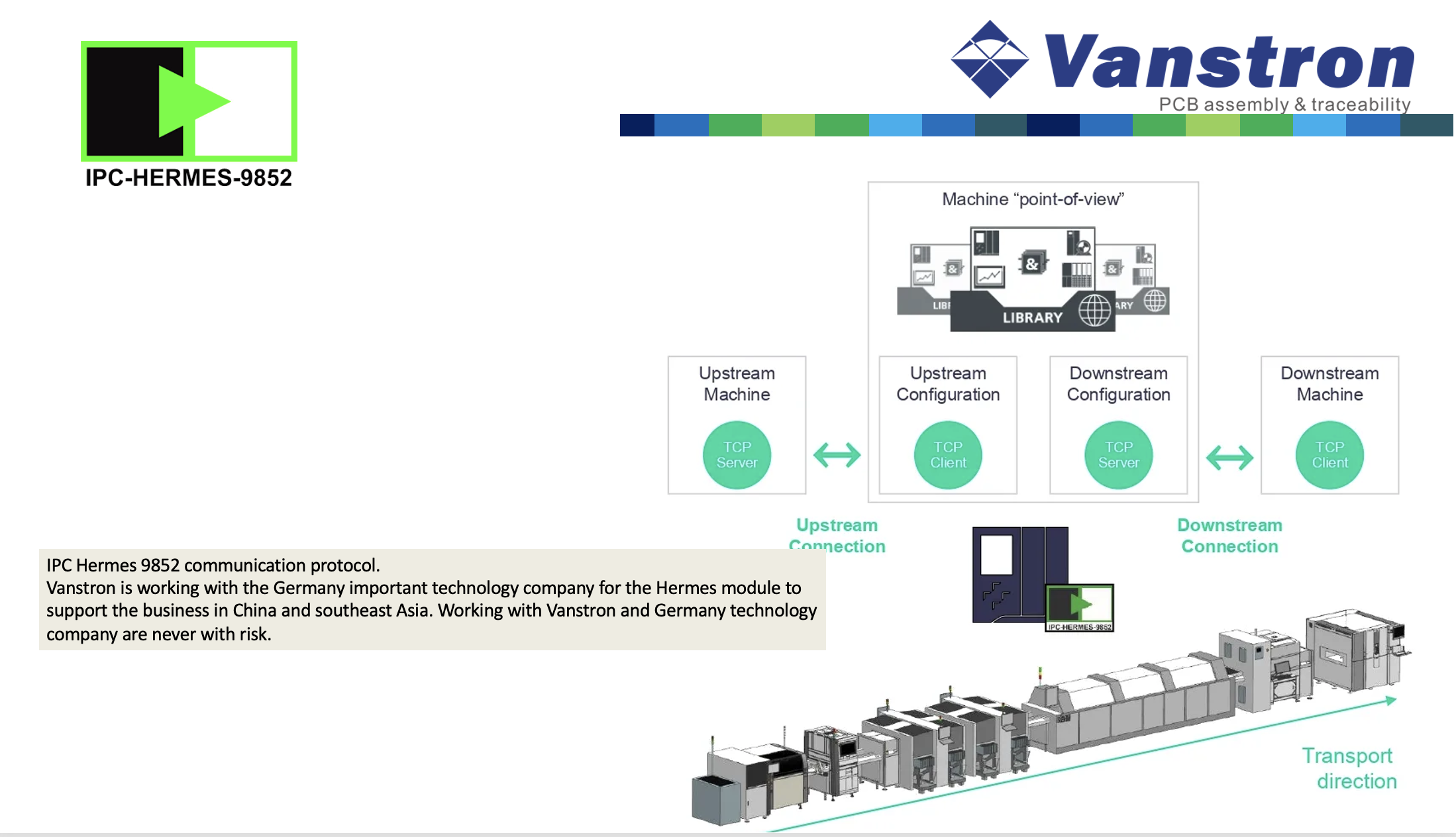

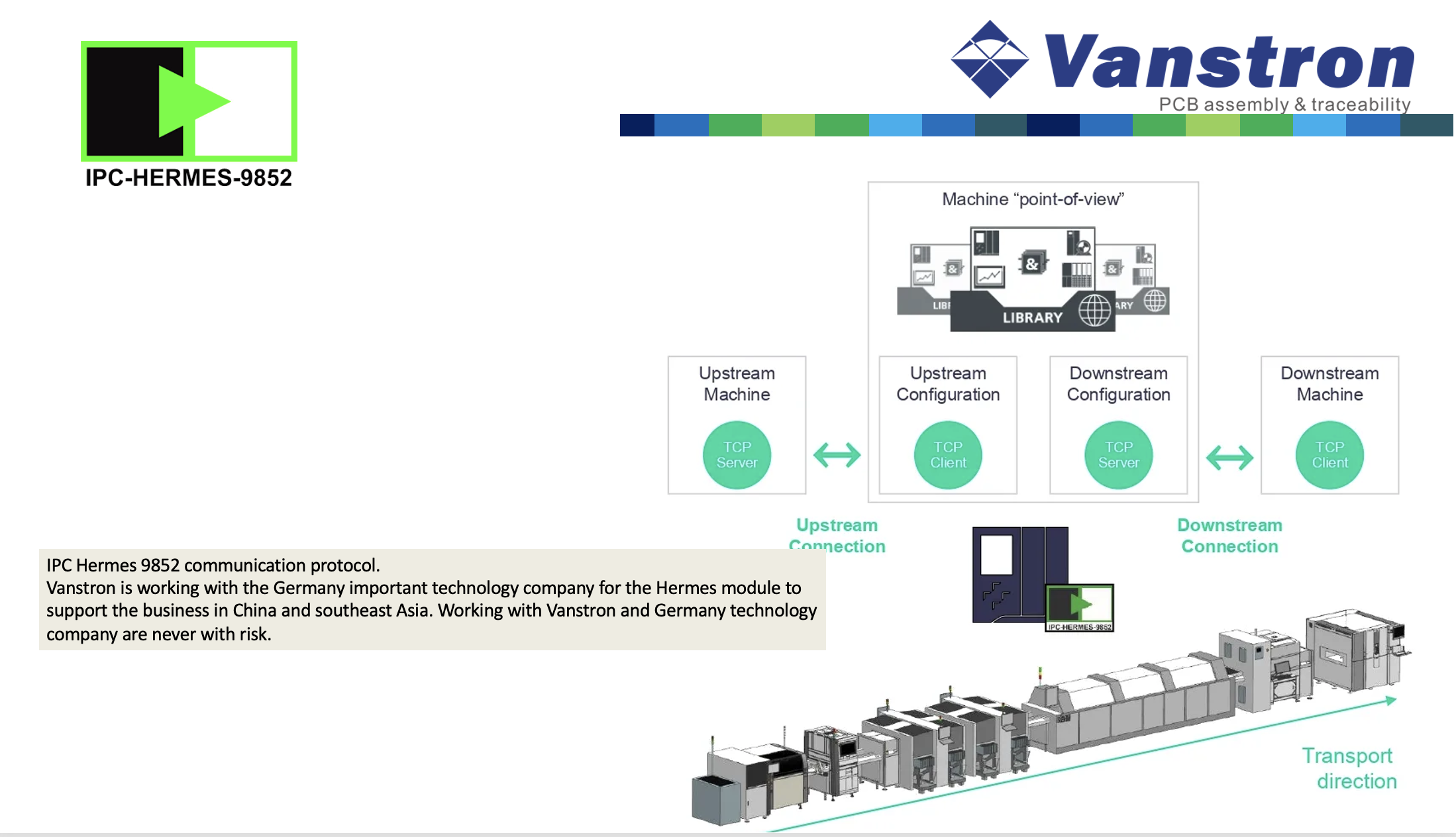

The IPC Hermes 9852, also known simply as Hermes, is a globally recognized communication protocol designed for equipment in SMT production lines. It replaces the older SMEMA standard, providing enhanced capabilities for data transfer and machine-to-machine communication. Hermes facilitates the exchange of board-related information such as barcode data, dimensions, and production status without the need for additional hardware. This makes it a more efficient and cost-effective solution for modern PCB manufacturing.

Vanstron’s Implementation of IPC Hermes 9852

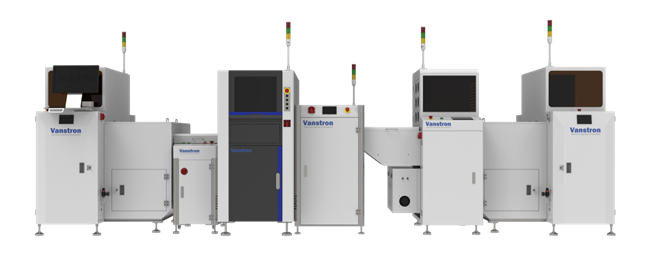

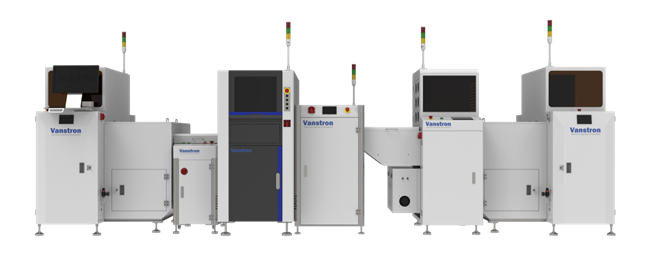

Vanstron’s boards handling machines, including loaders, unloaders, conveyors, and buffers, now come equipped with the IPC Hermes 9852 protocol. This integration offers several key advantages:

1. Seamless Connectivity

Vanstron’s machines can easily communicate with other Hermes-compliant equipment in the production line, eliminating bottlenecks and ensuring a smooth transition of PCBs between processes.

2. Enhanced Data Exchange

The protocol allows for the transfer of vital information, such as PCB identification, size, and process requirements, directly between machines. This improves traceability and enables real-time monitoring of production.

3. Future-Proofing Manufacturing Lines

By adopting Hermes, Vanstron ensures that its equipment is compatible with next-generation SMT production lines, meeting the demands of Industry 4.0 and beyond.

4. Ease of Integration

For manufacturers upgrading from older standards like SMEMA, Vanstron provides machines that support both protocols, ensuring a seamless transition without interrupting production.

Benefits for PCB Manufacturers

The adoption of Hermes in Vanstron’s boards handling machines aligns with the growing need for intelligent automation and traceability in PCB production. Here’s how manufacturers benefit:

• Improved Efficiency: Automated data transfer reduces manual input and errors, accelerating production processes.

• Traceability: Detailed tracking of PCB information throughout the production line ensures compliance with quality standards.

• Scalability: Hermes-enabled machines are adaptable to diverse production environments, whether for small-scale prototypes or large-volume manufacturing.

Vanstron: Driving Innovation in SMT Automation

Vanstron’s integration of the IPC Hermes 9852 standard underscores its position as a pioneer in SMT automation. By offering machines that combine advanced communication protocols with precision engineering, Vanstron empowers PCB manufacturers to achieve greater efficiency, reliability, and traceability in their operations.

Conclusion

As PCB manufacturing evolves, the demand for smarter, more interconnected production lines continues to grow. Vanstron’s boards handling machines, equipped with the IPC Hermes 9852 standard, provide a future-ready solution for manufacturers seeking to optimize their processes and embrace the benefits of Industry 4.0.

For more information about Vanstron’s boards handling machines and their capabilities, visit Vanstron’s website or contact us today.