The Role of Inline Laser Marking Machines in PCB Electronics Manufacturing

In the rapidly advancing field of electronics manufacturing, precision and traceability are critical factors for ensuring product quality and compliance. Inline laser marking machines have become an indispensable tool in the production and assembly of printed circuit boards (PCBs), providing manufacturers with the ability to meet stringent requirements while boosting efficiency.

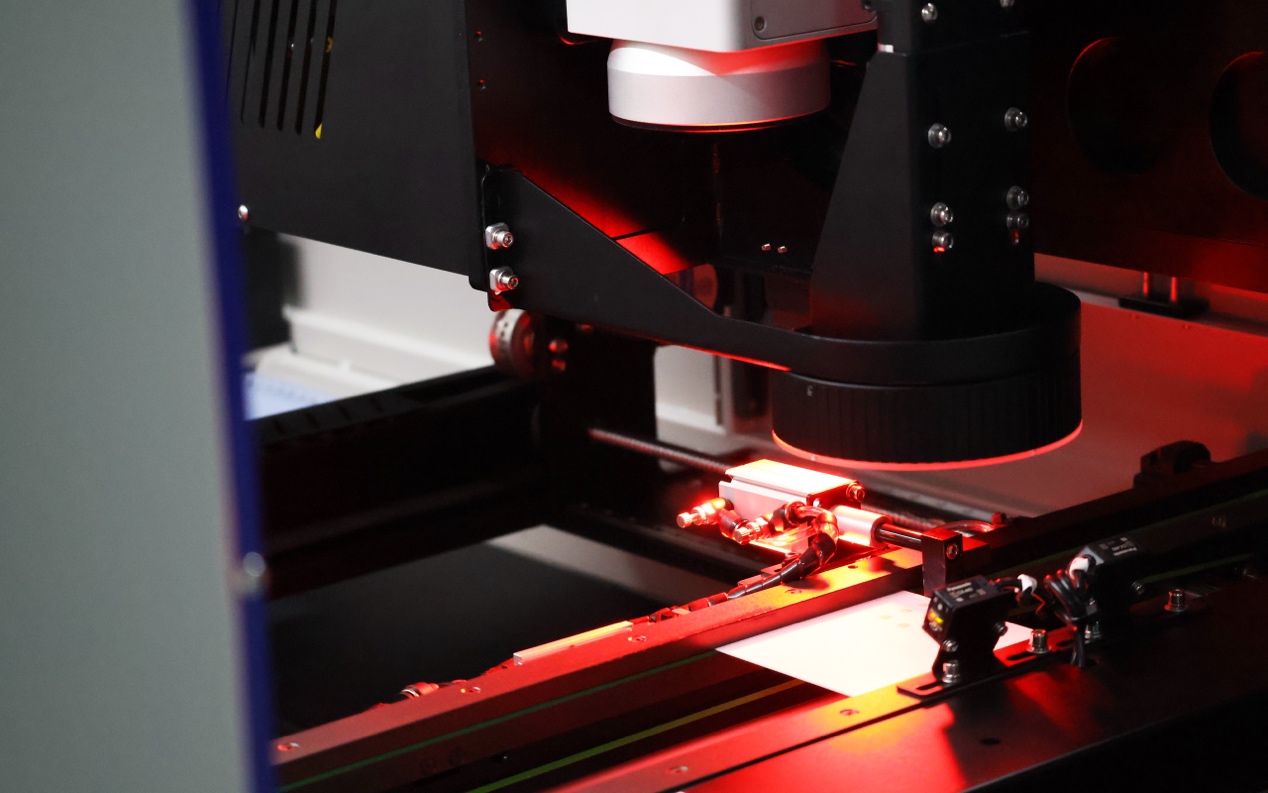

What Is an Inline Laser Marking Machine?

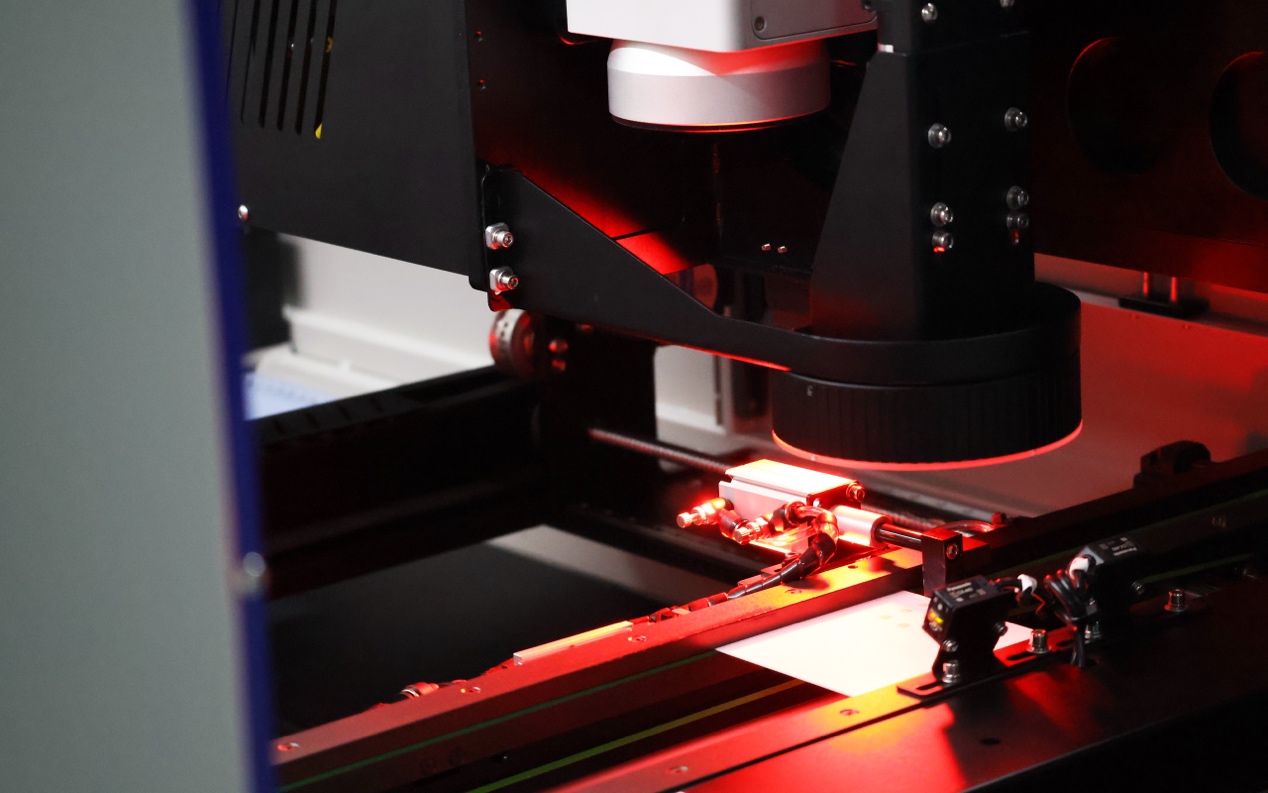

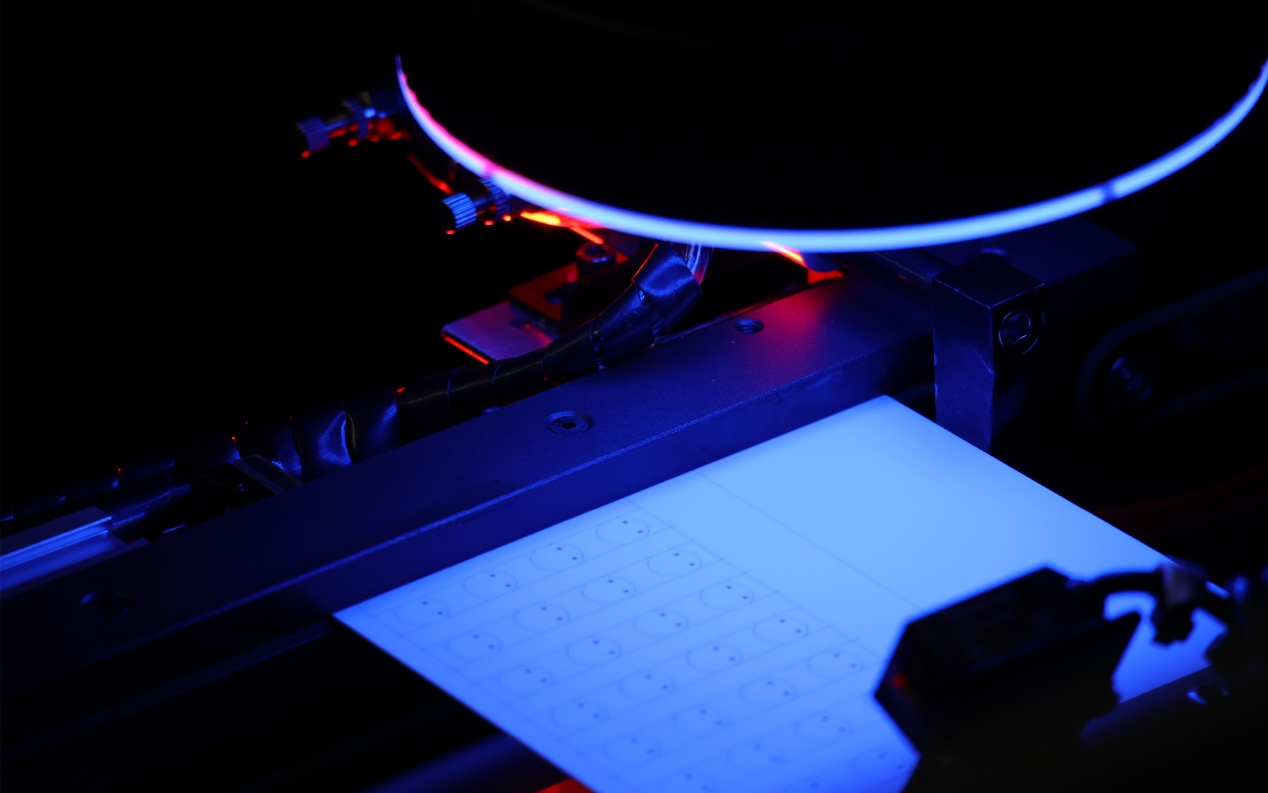

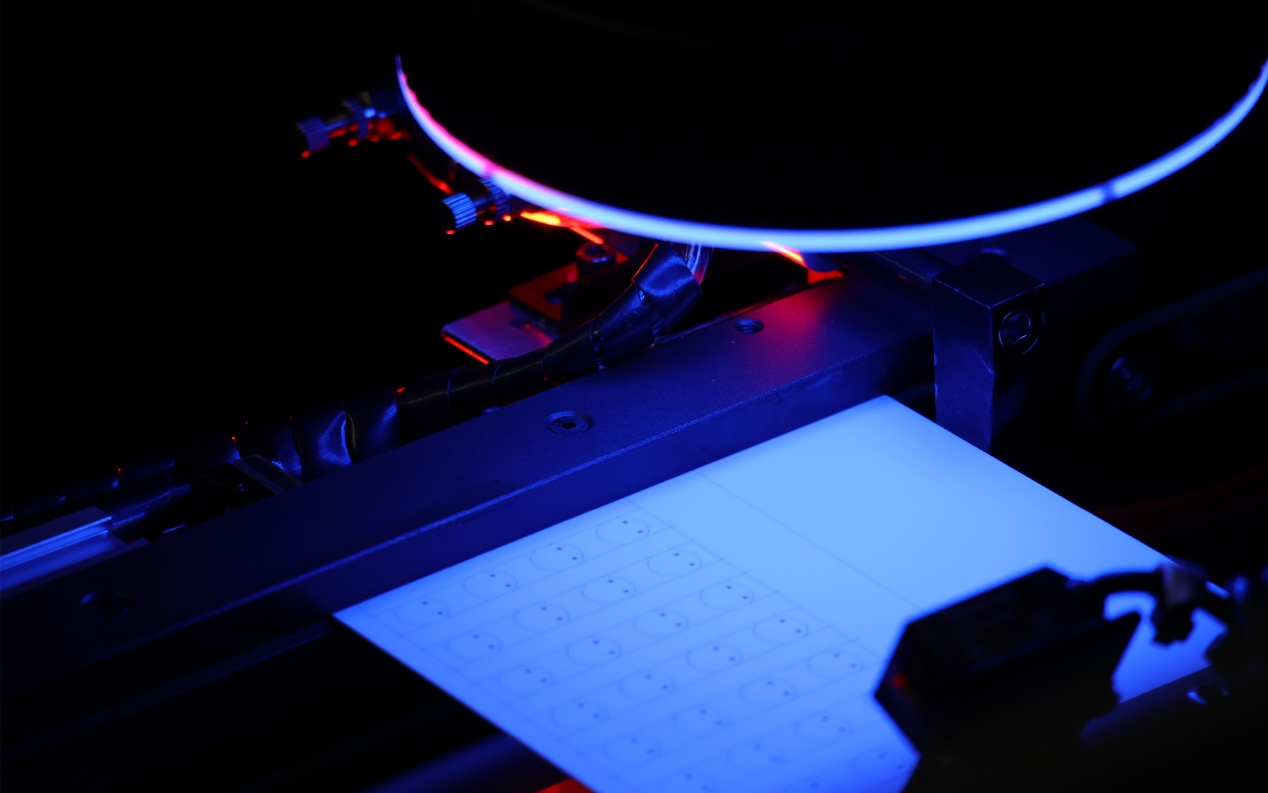

An inline laser marking machine is a specialized piece of equipment designed to engrave or etch high-precision markings directly onto PCBs during the manufacturing process. These markings typically include serial numbers, barcodes, QR codes, or logos, enabling traceability, identification, and quality control throughout the product lifecycle.

Key Benefits of Inline Laser Marking Machines in PCB Manufacturing

1. High Precision and Accuracy

Inline laser marking machines use advanced laser technology to create permanent, highly detailed markings without damaging sensitive PCB components. This precision ensures that even the smallest QR codes or text remain legible under challenging conditions.

2. Enhanced Traceability

Traceability is vital in electronics manufacturing for meeting regulatory compliance and maintaining quality assurance. Laser-marked barcodes and serial numbers allow manufacturers to track individual boards through the entire production process, reducing errors and simplifying warranty claims.

3. Non-Contact and Non-Damaging Process

Unlike traditional labeling or printing methods, laser marking is a non-contact process that doesn’t exert mechanical pressure on PCBs. This ensures the structural integrity of the board is preserved, making it ideal for delicate or high-density PCBs.

4. Durable Markings

Laser markings are resistant to environmental factors such as heat, chemicals, and abrasion, making them highly reliable for long-term use in critical electronics applications.

5. Seamless Integration with SMT Lines

Inline laser marking machines are designed for smooth integration with surface-mount technology (SMT) production lines. Their compact design and automation capabilities ensure that marking operations do not disrupt production flow, significantly improving throughput.

Applications in PCB Electronics Manufacturing

1. Product Identification and Branding

Many manufacturers use laser marking to engrave logos or part numbers onto PCBs for branding purposes. This enhances brand recognition while ensuring consistent product labeling.

2. Quality Control and Compliance

Inline laser marking enables real-time marking of quality inspection data or compliance codes directly onto PCBs, helping manufacturers meet global regulatory standards.

3. Tracking and Data Management

Laser-engraved barcodes and QR codes allow seamless integration with production monitoring systems. This facilitates data collection, enabling manufacturers to optimize processes and minimize defects.

4. Customization for Specialized Applications

Whether for automotive, medical devices, or consumer electronics, inline laser marking machines can handle a variety of PCB substrates, from FR4 to aluminum or copper, meeting the unique requirements of each industry.

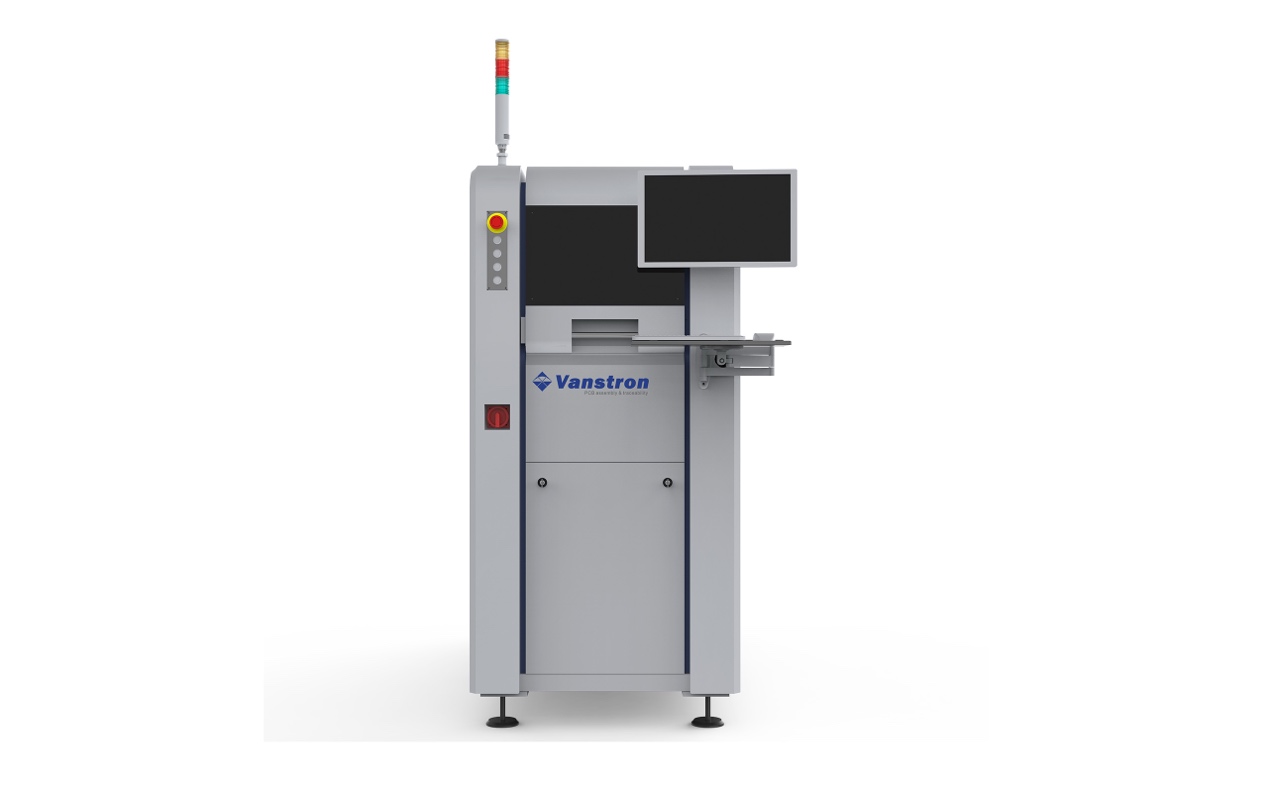

Why Choose Vanstron Inline Laser Marking Machines?

At Vanstron, we specialize in cutting-edge inline laser marking solutions tailored to the PCB manufacturing industry. Our machines are equipped with high-speed, high-precision CO2 and fiber laser technologies, ensuring exceptional performance and durability. Key features include:

• Seamless integration with SMT production lines.

• User-friendly interfaces and robust software for efficient operation.

• Compatibility with a wide range of PCB materials and sizes.

• Customizable solutions to meet specific manufacturing needs.

Conclusion

Inline laser marking machines are transforming the way PCBs are manufactured, offering unparalleled precision, reliability, and traceability. For manufacturers aiming to stay ahead in the competitive electronics market, adopting advanced laser marking technology is no longer an option but a necessity.

Explore Vanstron’s state-of-the-art inline laser marking machines today and see how we can enhance your PCB manufacturing process.

Contact us now to learn more!

Optimize your PCB manufacturing process with Vanstron. Visit www.vanstron.com for cutting-edge inline laser marking solutions.