Application

•PCB Curing: Adhesives, solder mask, conformal coating, and other thermal processes.

•SMT Assembly: Seamless integration into automated production lines.

•Electronics Manufacturing: Suitable for a wide range of components and substrates.

Key Features:

• Space-Saving Vertical Design: Maximizes factory floor space while maintaining high throughput.

• Precision Temperature Control: Ensures uniform curing across all PCBs.

• Multi-Layer Configuration: Supports simultaneous processing of multiple PCBs for enhanced productivity.

• Energy Efficiency: Reduces power consumption without compromising performance.

• CE-Certified Reliability: Meets international safety and quality standards.

• Customizable Settings: Adjustable curing time, temperature, and process parameters to suit specific production requirements.

Using innovative control, blower, heating and sensor components combined with a solid machine design, Vanstron supplies a high-quality system enabling you to run and log stable processes in your production operations.

Products name & Model: VBH- series |

Descriptions |

Inline Drying / Curing oven- (Vertical Buffer type) |

|

Model |

VBH-250 |

VBH-90 |

Standard Configuration

|

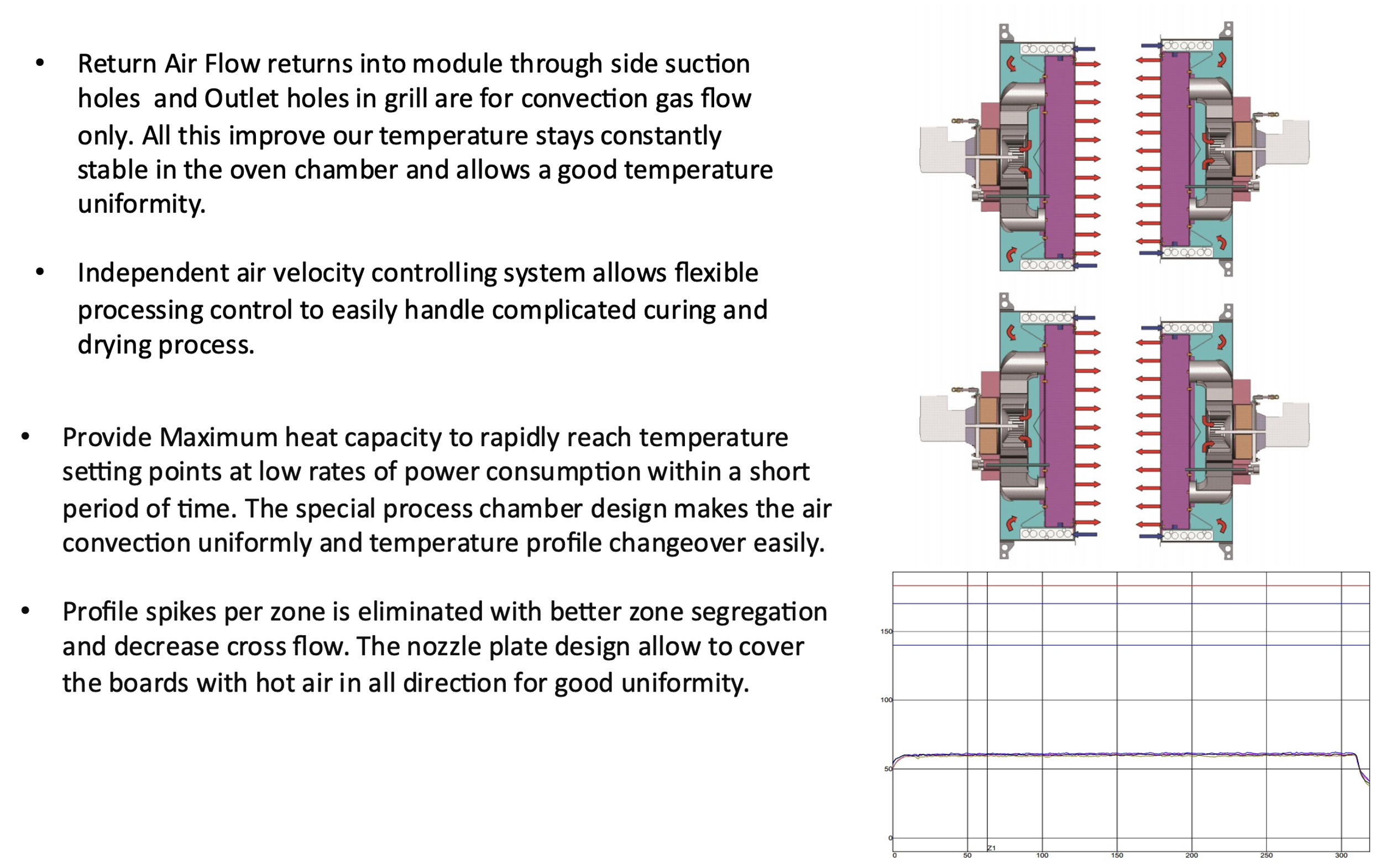

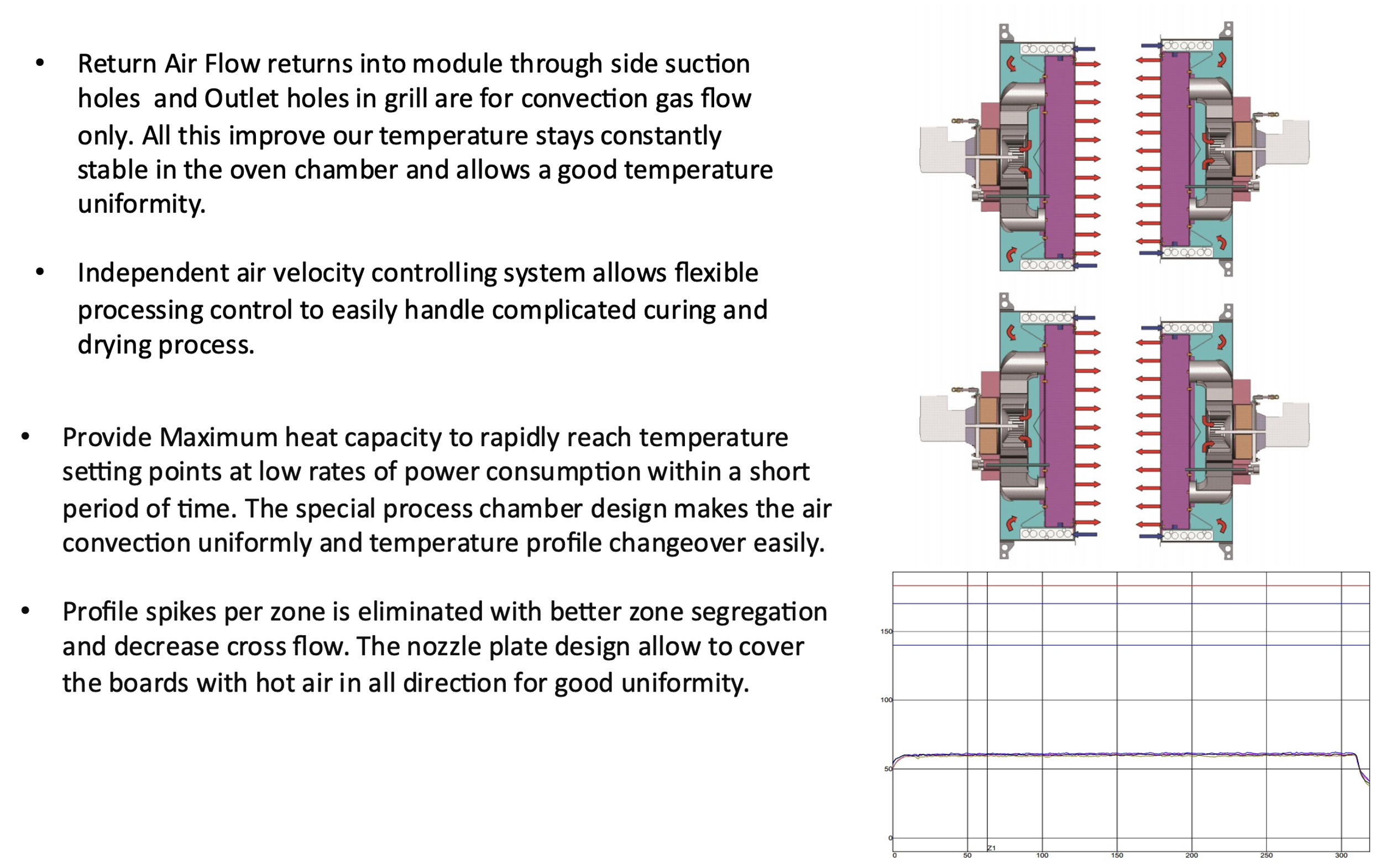

Heating system

|

12 Heating module system ( Depends on different application) |

Forced convection heating |

Hot air speed adjusting by software; |

Temperature uniformity across pallet: +/-2°C; |

VBH-250 |

VBH-90 |

Temperature effective range : Room temperature to Max.200°C; |

Temperature effective range : Room temperature to Max.90°C; |

Temperature control : PID closed loop control +SSR drive; |

Transportation system

|

Conveyor direction: right to left |

Conveyor heights:900mm+/-50mm |

Conveyor width adjustable from 50*460mm |

Max. length of product available: 50-500mm; |

Conveyor width adjustments: automatic |

Products components heights: customized solution |

Buffer stock capacity: customized. |

Per Boards keeping time in the oven programming by user |

VBH-250 |

VBH-90 |

Boards or pallet per weight: 5kg Max. |

Boards or pallet per weight: 2.5kg Max |

Pallet process edge distance:5mm (or specified) |

Easy eye-level access to internal controls; |

international standard SMEMA interface |

Control system

|

PLC controller + touch screen software |

-Temperature abnormal alarm |

-Board dropped alarm system |

-PID close loop temperature control |

- Error diagnosis system; |

- Operator password management |

-SMEMA communication |

Fume exhaust system |

Standard exhaust system |

Electrical system |

-CE certificates supported;

Power supply: 380 V ,3 Phase 50hz; |